Intelligent Steel Pipe Internal and External Epoxy Anti-Corrosion Production Line Exported Globally

Product Description

Our Internal Anti-Corrosion Coating Line Pipe with 3PE and 2PE systems is designed for optimal protection of steel pipes used in harsh environments. The advanced 3-layer polyethylene (3PE) coating provides superior corrosion resistance, while the 2-layer polyethylene (2PE) coating ensures durability and reliability. Ideal for oil, gas, and water pipeline applications, this solution guarantees long-lasting performance and reduced maintenance costs, offering excellent protection against external and internal corrosion.

The pipe coating line meets the requirements of producing the steel pipe with coating which meets international standards DIN30670-1991,CAN/ Z245.21-2010,ISO21809-1-2009 SY/T 0413-2002, GB/T23257-2009,GOST 9.602-2016, GOST R 51164-98, GOST31448, GOST31445

The coating line mainly consists of the following units:

-steel pipe conveyor system

-shot/sand blasting system

-dust collector system

-pipe induction heating system

-epoxy powder spraying system

-PE&Adhesive coating system

-water cooling system

-pipe end cutting system

-hydraulic and pneumatic system

-testing system

-electronic control system

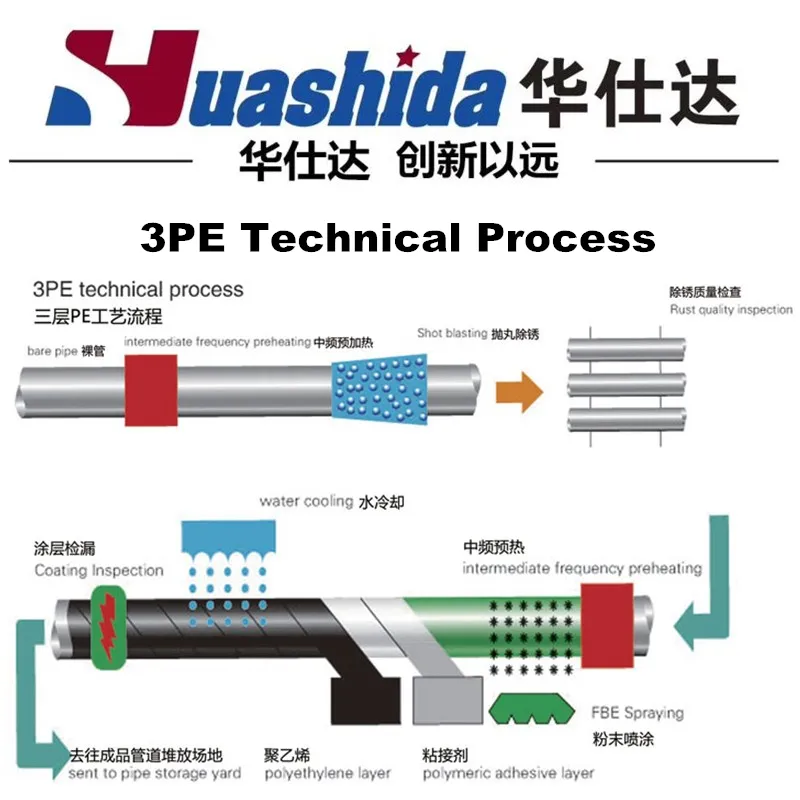

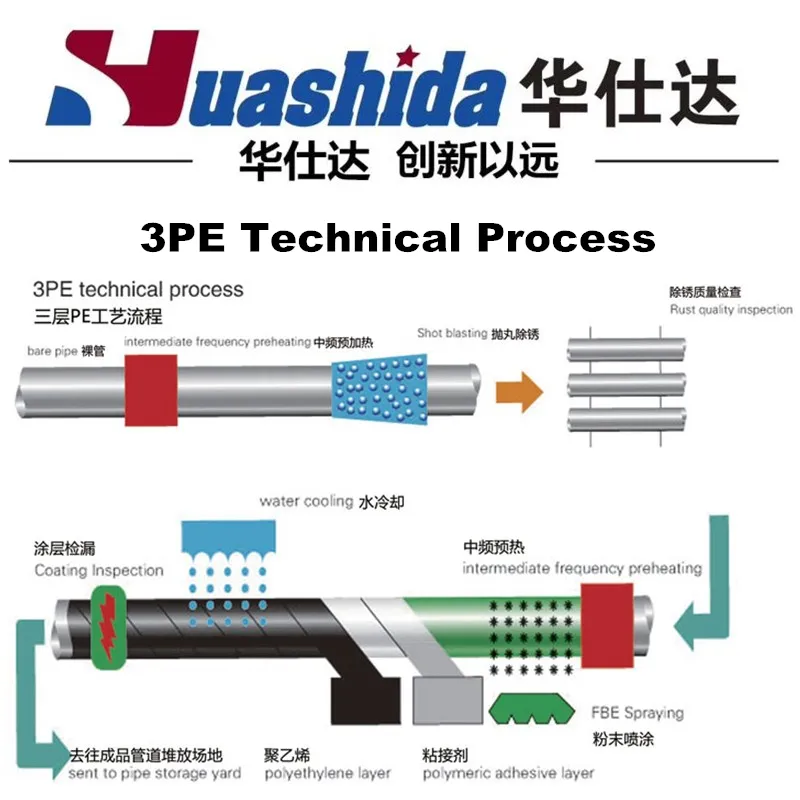

Technological process of 3LPE coating:

Pipe uploading→Shot blasting→Medium frequency induction heating→Epoxy powder spraying→Adhesive and polyethylene coating→Water cooling→Pipe end cutting back→Bevelling→Pipe unloading

The line can be customized to fit individual layout and application.

Product Parameters

Main Equipment List and specification

| No. |

Name |

Specification |

| A. Surface Cleaning Equipment |

| 1 |

Steel pipe conveyor |

Adjustable speed and angle, pipe uploading and unloading controlled by PLC |

| 2 |

Shot blasting machine |

|

| 3 |

Cyclone dust collector |

High efficient downwind cyclone dust removal |

| 4 |

Impulse cartridge dust collector |

|

| 5 |

Centrifugal fan |

|

| 6 |

PLC control system |

Automatic control of the line |

| B. Coating Equipment |

| 1 |

Spiral pipe conveyor |

Adjustable speed and angle |

| 2 |

Induction heating machine |

|

| 3 |

Powder spraying device |

Spraying thickness 80-800μm |

| 4 |

Automatic feeder&dryer |

|

| 5 |

SJ-65/30 Extruder |

|

| 6 |

SJ-180/30 Extruder |

|

| 7 |

Adhesive extruder die mould |

High quality die steel |

| 8 |

PE sheet extruder die mold |

High quality die stee |

| 9 |

Adhesive/PE sheet coating device |

Pressing roller with silicon coating and internal cooling |

| 10 |

Environmental Protection Ventilation equipment |

|

| 11 |

Cooling Spray equipment |

|

| C.Platform Equipment |

| 1 |

Steel pipe platform |

High quality |

| D.Groove Equipment |

| 1 |

PE Beveling Machine |

Steel brush disk, |

| 2 |

Hydraulic Lifting and Turning Machinery |

For lifting and turning the pipe |

| 3 |

Hydraulic Equipment |

|

Equipment show

Pipe usage

3 layer PE anti-corrosion coating consist of first FBE coating, middle adhesive layer, and outer polyethylene layer.

The three-layer polyethylene anti-corrosion coating utilizes cutting-edge technology as the outer protective layer for buried pipelines. It is commonly used to protect gas and oil transmission lines, urban gas systems, water supply pipes, and other fluid transport pipelines. The 3PE coating enhances the mechanical strength of the pipeline, offering exceptional electrical resistance, waterproofing, wear resistance, and anti-aging capabilities

Our factory

Qingdao Huashida, established in 2003, covers a construction area of over 34,000 square meters. Since its inception, the company has continuously expanded its facilities to accommodate the growing demand for high-quality machinery and equipment. The spacious premises house state-of-the-art production lines, research and development centers, and comprehensive testing areas, enabling us to offer cutting-edge solutions to our global clients. With this large-scale infrastructure, we are able to efficiently manage production, ensure precision, and maintain the highest standards in manufacturing.

We have fully equipped in-house workshops for machining, welding, coating, and assembly, ensuring complete control over every stage of the production process. Our dedicated teams work with precision and expertise to deliver high-quality components, from initial machining to the final assembly. By managing these processes internally, we guarantee the highest standards of craftsmanship, efficiency, and consistency in every product we create.

Customer visiting

We have received customers from Russia, Ukraine, Belarus, Kazakhstan, Uzbekistan, Iran, India, Brazil, Egypt and other countries to visit the factory for inspection and ordering.

Delivery

We have delivered our equipment to Russia, Kazakhstan, Uzbekistan, Belarus, Iran and other countries.

HUASHIDA at international exhibitions

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!