This is an advanced technology widely used for steel pipe corrosion protection. Epoxy powder coating is evenly applied to the surface of the steel pipe through electrostatic spraying, and then cured by heating to form a strong, continuous protective coating.

Main Features

The core process consists of three main stages:

1. Surface Pretreatment

This is the most critical step, ensuring coating adhesion. The steel pipe undergoes:

Cleaning: Removing oil and grease.

Shot Blasting/Sandblasting: Thoroughly removing rust, old paint, and impurities, creating a rough, anchor-patterned surface.

Preheating: Heating the steel pipe to a suitable temperature to remove moisture and prepare for spraying.

2. Powder Coating and Curing

Electrostatic Spraying: In a specialized spray booth, negatively charged epoxy powder is atomized by a spray gun and evenly adhered to the grounded (preheated) steel pipe surface due to electrostatic attraction.

Heat Curing: The sprayed steel pipe enters a curing oven. The powder melts, flows, and undergoes a cross-linking chemical reaction at high temperature, forming a dense, strong, inert coating. 3. Cooling and Testing

After the steel pipes are removed from the curing oven, they are cooled to room temperature by water or air.

Final testing is then performed, including coating thickness, continuity (electro-spark pinhole testing), and adhesion testing, to ensure quality meets standards.

Process Advantages:

Superior Corrosion Resistance: The coating is chemically inert, resistant to corrosion, acids, and alkalis, providing long-term protection (up to 50 years or more).

High-Strength Adhesion: The coating combines mechanical and chemical bonding with the steel pipe surface, making it difficult to peel off.

Environmentally Friendly and Efficient: The powder is recyclable, with virtually no solvent evaporation (VOCs), meeting environmental requirements.

Uniform Coating: Thickness can be precisely controlled, covering complex shapes such as welds and edges.

Application fields

Oil and Gas Pipelines

Urban Water Supply and Drainage Pipelines

Chemical Fluid Transportation Pipelines

Building Structural Pipe Piles

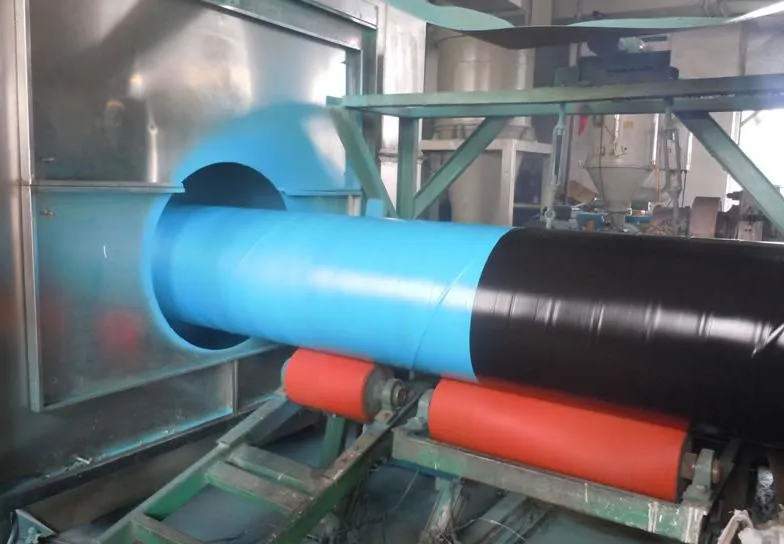

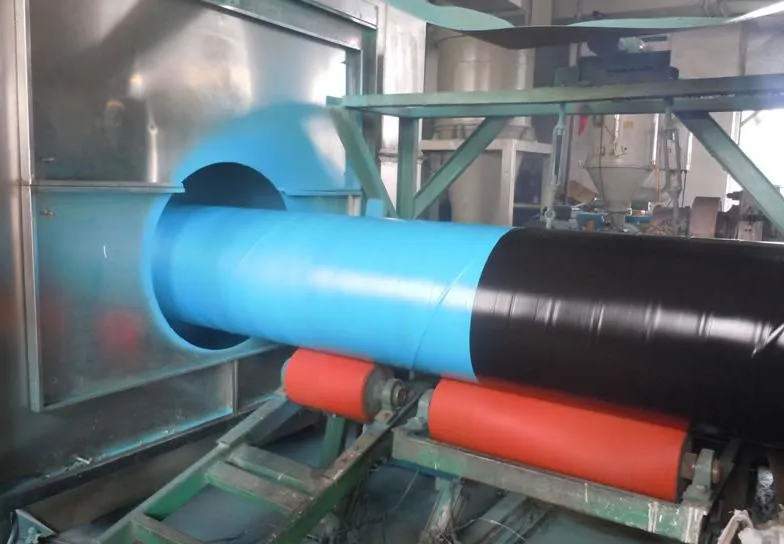

3-layer PE coating comprises:

1. Initial FBE primer

2. Intermediate adhesive layer

3. External polyethylene sheath

The production line adopts a three-layer composite protective structure:

First layer: Fusion Bonded Epoxy (FBE ≥ 100 µm)

Second layer: Adhesive (AD 170-250 µm)

Third layer: Polyethylene (PE 2.5-3.7 mm)

The complete system includes external shot blasting and derusting line, epoxy spraying system, intermediate frequency heating unit, hot-melt adhesive and polyethylene extrusion systems, cooling and conveying platforms, and a fully automated control system.

Each process is strictly monitored through the ISO9001-certified quality management system, ensuring reliable coating adhesion, outstanding corrosion resistance, and long service life of the pipeline.

Huashida's 3PE coating lines have been widely applied in oil and gas transmission, water supply, and district heating projects, and exported to the Middle East, Russia, Africa, Turkey, and Korea, earning an excellent reputation for stable performance and dependable quality

Product Parameters

Processable pipe diameter: Φ159 mm - Φ1220 mm

Coating thickness: 80 µm - 800 µm

Daily output: up to 3-8 km

Annual capacity: approx. 2 million m² (referenced to Φ508 mm pipe)

Standards compliance: SY/T0413-2002, GB/T23257-2009, DIN 30670, NACE and other international/industry standards.

Main Equipment of 3PE anticorrosion processing

Configuration List

| No. |

Name |

Set |

| A. Derusting Equipment |

| 1 |

Pipe-converying Equipment |

1 |

| 2 |

Shot Blast Cleaning Machine |

1 |

| 3 |

Cyclone Dust Collector |

1 |

| 4 |

Pulse dust collector |

1 |

| 5 |

Centrifugal exhaust fan |

1 |

| 6 |

Rust removal equipment PLC |

1 |

| B. Coating equipment |

| 1 |

Coating transfer equipment |

1 |

| 2 |

IF heating device |

1 |

| 3 |

Powder spraying device |

1 |

| 4 |

Automatic loading dryer |

2 |

| 5 |

SJ-65/30 Extruder |

1 |

| 6 |

SJ-180/30 Extruder |

1 |

| 7 |

Hot melt adhesive extruder die |

1 |

| 8 |

PE sheet extruder head mold |

1 |

| 9 |

Hot melt adhesive/PE sheet coating device |

1 |

| 10 |

Environmental Protection Ventilation equipment |

1 |

| 11 |

Cooling Spray equipment |

1 |

| C.Platform Equipment |

| 1 |

Steel pipe platform |

1 |

| 2 |

Post-rust removal transition platform |

1 |

| 3 |

Product tube storage platform |

1 |

| 4 |

Hydraulic Equipment |

3 |

| D.Groove Equipment |

| 1 |

PE Beveling Machine |

2 |

| 2 |

Hydraulic Lifting and Turning Machinery |

1 |

| 3 |

Hydraulic Equipment |

1 |

| 4 |

PLC |

1 |

| E.Compressed air Equipment |

| 1 |

Screw Air Compressor |

1 |

| 2 |

Cold dry machine |

1 |

| 3 |

Precision filters |

3 |

| 4 |

Gas tanks |

1 |

FAQ

Q: What pipe diameters can the line handle?

A: The equipment covers four standard ranges: 48-219 mm, 219-1220 mm, 800-1600 mm, and 1000-2400 mm.

Q: What blasting cleanliness grade is achieved?

A: Sa 2½ (near-white metal) per ISO 8501-1.

Q: What anti-corrosion coating standards are met?

A: The line complies with SY/T0413-2002, DIN 30670, and other international standards.

Q: What is the delivery time?

A: 2-3 months after deposit.

Q: What is the production output?

A: Up to 3-8 km per day; annual capacity 2 million m² (based on Φ508 mm pipe).

Q: What coating thickness can be applied?

A: 80-800 µm.

Q: Where has the 3PE equipment been sold?

A: Russia, Iran, UAE, India, Belarus, Kazakhstan, and more.

Q: What after-sales services are provided?

A: 12-month warranty on mechanical parts, 6-month on electrical parts, plus technical support, training, and operator guidance.

Packaging & Shipping

Company Profile

Exhibition

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!