Cold-applied anticorrosion tape making machine is designed for producing the PE tape for protection of underground or overhead pipelines in oil, gas, petrochemical, and wastewater industries.

The equipment mainly consists of three parts: PE base film extrusion production line, Adhesive coating equipment, and slitting equipment.

Technological processes

The production process of cold-applied tape typically includes the following main steps:

-

Base Film Extrusion

-

Raw Material Preparation: Polyethylene (PE) is prepared as the base film raw material.

-

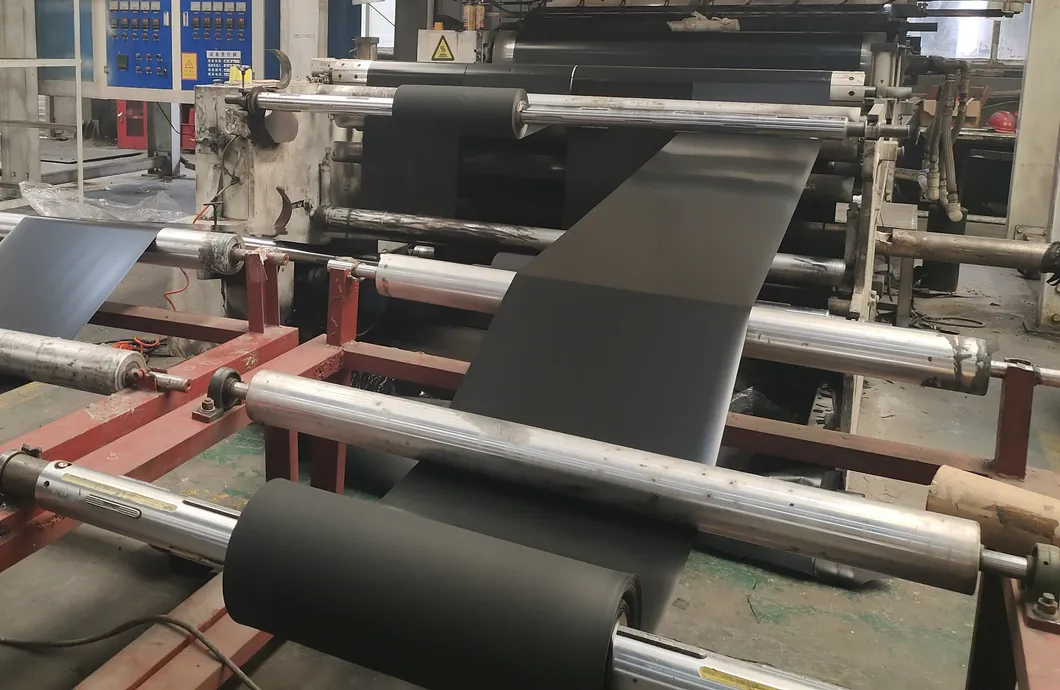

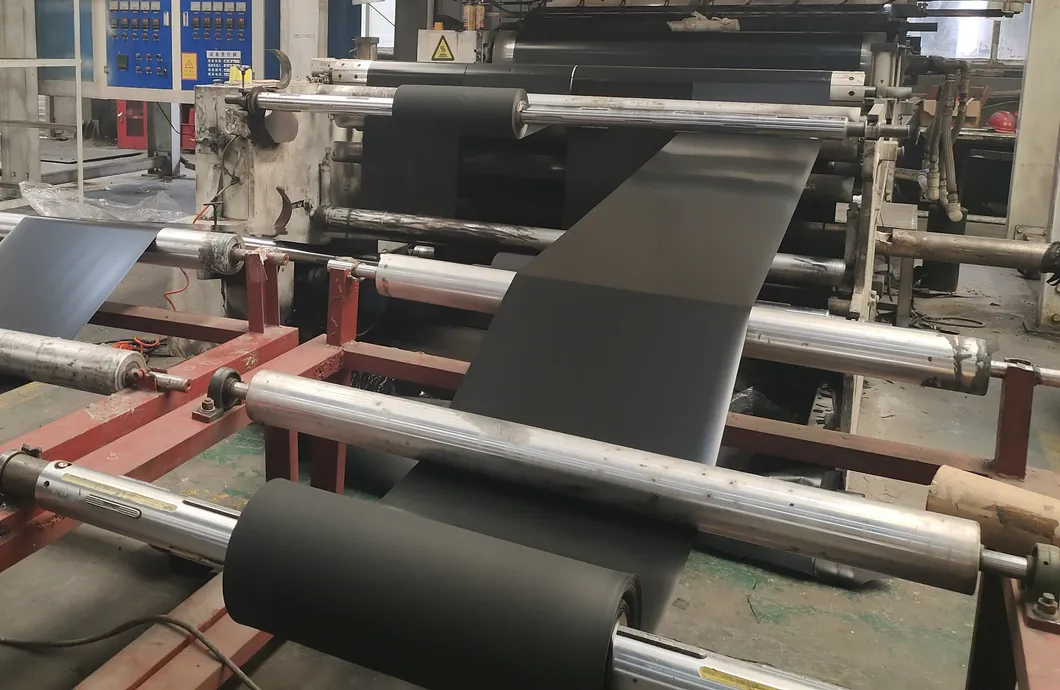

Extrusion Molding: The raw material is heated and melted in an extruder, then molded through a die to form a continuous base film.

-

Cooling and Shaping: The extruded base film is cooled and shaped using cooling rollers to ensure uniform thickness and consistency.

-

Adhesive Coating

-

Adhesive Preparation: Butyl rubber are prepared to ensure proper viscosity and stability.

-

Coating Process: The adhesive is evenly applied to one or both sides of the base film using coating equipment to form an adhesive layer.

-

Slitting

-

Slitting Preparation: The coated base film roll is prepared, and the parameters of the slitting equipment are adjusted.

-

Slitting Operation: The wide roll is slit into cold-applied tapes of the required width using slitting equipment.

-

Winding and Packaging: The slit cold-applied tapes are wound into rolls, packaged, and prepared for shipment.

Product Parameters

Equipment ListPE basing file extrusion line

|

Equipment Name |

Quantity |

| 1 |

Vacuum automatic feeder |

1 |

| 2 |

Hopper dryer |

1 |

| 3 |

SJ-75X30 extruder |

1 |

| 4 |

Hydraulic screen changer |

1 |

| 5 |

Die head mold type 1000 |

1 |

| 6 |

Multi-roller tape-casting machine |

1 |

| 7 |

Winding machine |

1 |

| 8 |

PLC computer control system |

1 |

Adhesive coating machine

| No. |

Equipment Name |

Qua. |

| 1 |

Frame |

1 unit |

| 2 |

200N·M Magnetic powder brake + Silicone stick 1300mm with corona processor |

1 unit |

| 3 |

100N·M Magnetic powder brake |

1 unit |

| 4 |

100N·M magnetic powder clutch |

2 unit |

| 5 |

200N·M magnetic powder clutch |

1 unit |

| 6 |

Screw |

1 unit |

| 7 |

Force-feed device |

1 unit |

| 8 |

Constant pressure system |

1 unit |

| 9 |

Adhesive delivery pipe |

1 unit |

| 10 |

Winding machine |

1 unit |

| 11 |

Unwinding machine |

2 unit |

| 12 |

Coating compound equipment |

1 unit |

| 13 |

Main engine frequency converter |

1 unit |

| 14 |

Extruder frequency converter |

1 unit |

| 15 |

Thermal switch |

1 unit |

| 16 |

PLC |

1 unit |

Our Advantages

-Adopt advanced technology

-Stable operation

-High degree of automation, saving labor costs

-Good quality, meets international standard

-Supply full completed production solution: design, installation, commissioning,training

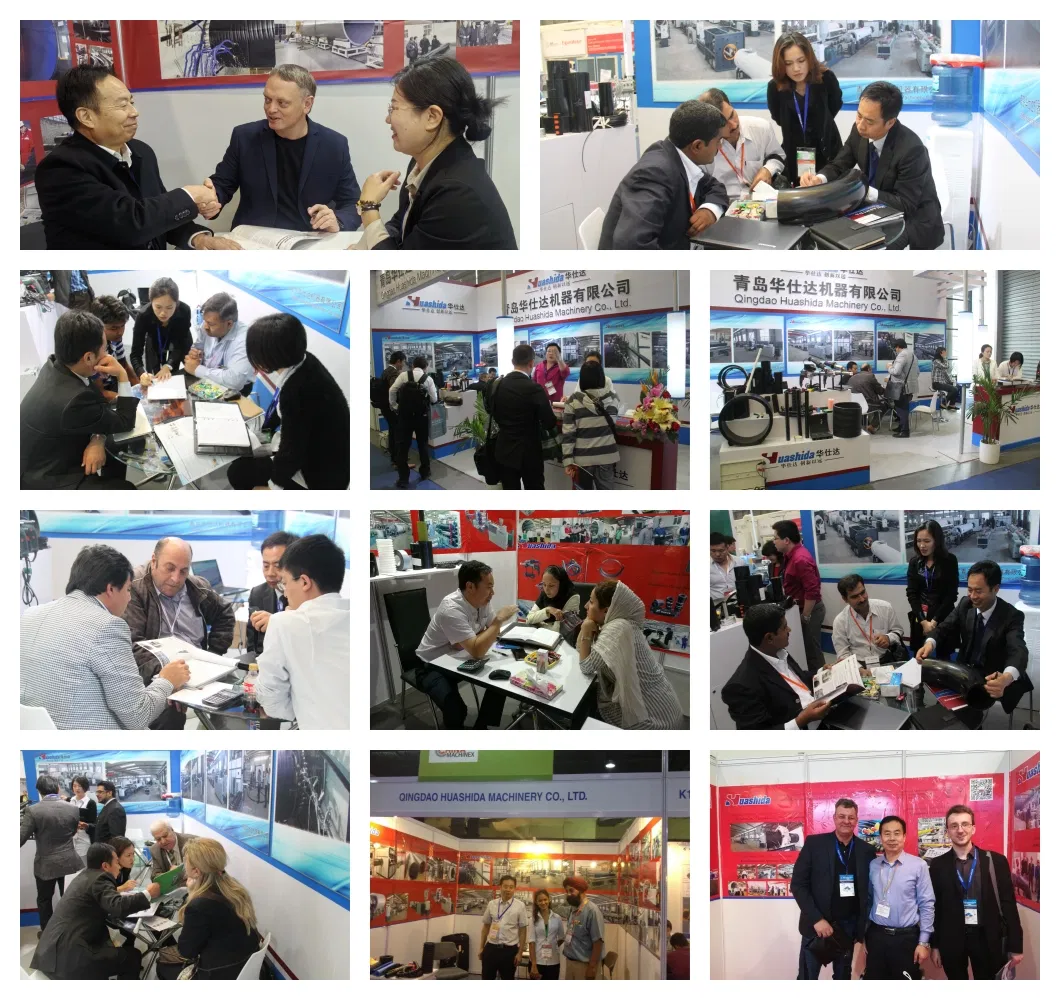

-Share you 389 sets of production experience from all the world

-Having 9 professional senior engineers

-Having a high-end plastic machinery equipment expert workstation in China

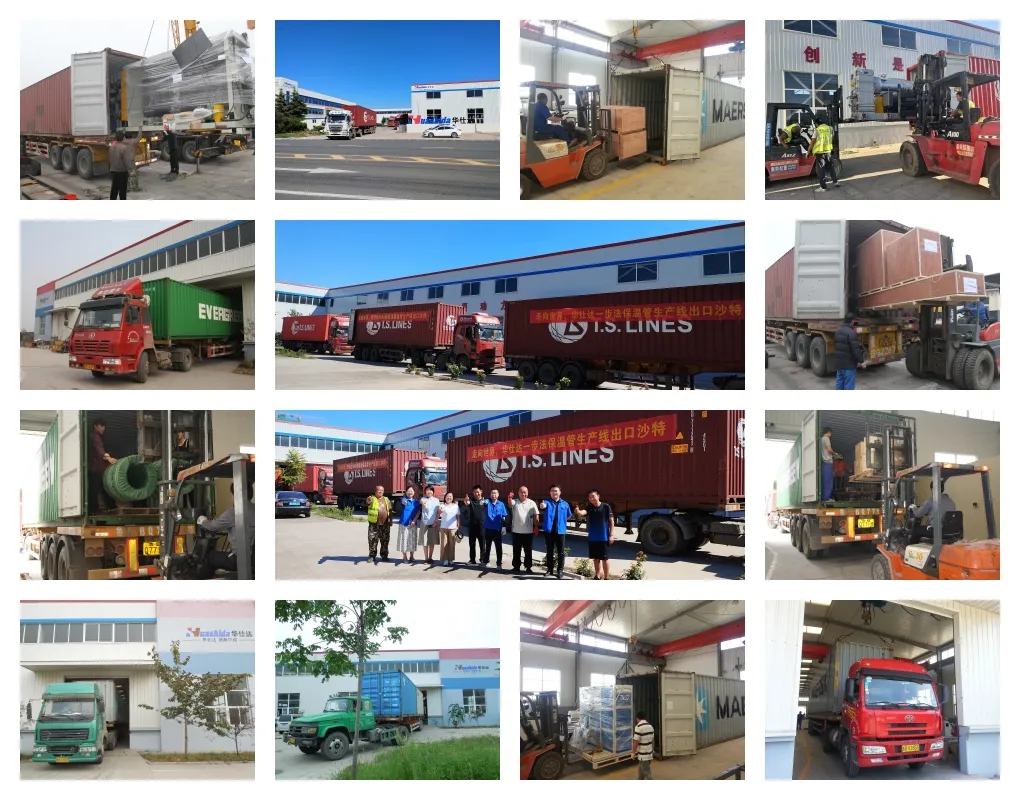

Customer cases

Company Profile

Qingdao Huashida Machinery Co., LTD, is a manufacturer of series of plastic pipe machines, municipal pipe machines, pipe insulation&anticorrosion machines, and pipe jointing&anticorrosion materials, with 21 years of production experience.

Our main products are:

1. HDPE jacket pipe for pre-insulated pipe Production Line (110-2000mm)

2. Rigid pre-insulated pipe Production Line

3. Flexible pre-insulated pipe(PERT) production line

4. Steel pipe FBE/2LPE/3LPE anti-corrosion coating line

5. Steel pipe derusting line

6. PE pressure pipe/Water Gas supply pipe production line

6. PP/PE plastic board/sheet/geomembrane production line

7. NBR PVC Thermal insulation tube/plate production line

8.Pipeline anti-corrosion materials and instruments: heat shrink joint coating sleeve, electro-fusion weldable joint sleeve, portable welding gun(extruder), PE PP welding rod.

We have been working with more than 400 overseas customers and exporting our products to Kazakhstan, Uzbekistan, Iran, Turkey, Russia, Nigeria and other countries.

Our team

Delivery

Exhibition

Certifications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!