eat Shrink Sleeve Machinery 3lpe preinsulated HDPE Pipeline Field shrinkable Joints

Product Description

Radiation cross-linked heat shrinkable sleeves are mainly used for field girth weld coating of 3LPE or thermal insulated pipelines, providing excellent anti-corrosion and waterproof protection for pipe joints, especially in plastic water supply and drainage systems.

The Huashida Brand Heat Shrinkable Sleeve Extrusion Line adopts a complete and advanced production process.

Step 1: The PE backing film extrusion line produces PE film according to customer requirements.

Step 2: The PE film is then sent to a professional irradiation facility for radiation cross-linking treatment, which enhances the film's fire resistance, tensile strength, and thermal stability.

Step 3: The irradiated film is transferred to the heat shrinkable sleeve adhesive coating line. In this stage, the film substrate is stretched twice to ensure an optimal shrink ratio. A specially formulated hot-melt adhesive is prepared in a professional reactor, extruded, and uniformly bonded with the cross-linked PE backing film.

The final product features high adhesion strength, excellent corrosion resistance, and stable shrink performance, meeting international standards for pipeline protection.

Product Parameters

1. PE back film extrusion Line

--- Single screw extruder

--- Die head

--- Three Calender

--- Roll temperature controlling system

--- Cooling rack

--- Hauling off

--- Rewinding machine

2. Adhesive Mixing and Coating Line

--- Unpowered uncoil device

--- Reactor

--- Adhesive coating system

--- Cooling water tank

--- Haul off

--- Coiler platform.

3. For three layer fiber reinforced heat shrink sleeve, we need to add below equipments

--- Fiber uncoiling device

--- Fiber heating device

--- Fiber flattening device

Cross-linked Heat Shrinkable Belt Production Line (model SRSG-800 )

| RS-800 Basic film extrusion line (RS-800) |

| 1 |

SJ-65×30 single screw Extruder |

1 Set |

|

| 2 |

T-Die mold |

1 Set |

|

| 3 |

3-Calender Roller |

1 Set |

|

| 4 |

Roll temperature control system |

1 Set |

|

| 5 |

Cooling Bracket |

1 Set |

|

| 6 |

Haul-Off Unit |

1 Set |

|

| 7 |

Coiler |

1 Set |

|

| TJ-700 adhesive mixing and coating line (TJ-700) |

| 1 |

Unpowered uncoil device |

1 Set |

|

| 2 |

Basic film drawing mill |

1 Set |

|

| 3 |

reactor |

1 Set |

|

| 4 |

Adhesive coating mold group |

1 Set |

|

| 5 |

Cooling water tank |

1 Set |

|

| 6 |

Haul-Off Unit |

1 Set |

|

| 7 |

Coiler platform |

1 Set |

|

Our Advantages

Adopts advanced manufacturing technology - ensures precision and high product consistency.

Stable and reliable operation - designed for long-term continuous production.

High degree of automation - reduces labor cost and improves efficiency.

Excellent anti-corrosion performance - meets international quality standards.

Complete production solution - includes design, installation, commissioning, and operator training.

Extensive global experience - over 389 production lines successfully operating worldwide.

Professional technical team - 9 senior engineers with rich industry expertise.

High-end expert workstation - certified plastic machinery R&D base in China.

Quality guarantee period: 12 months or 14 months from date of Bill of Lading.

The seller would send engineers to the buyer's factory to test the new machine and train people of the buyer.

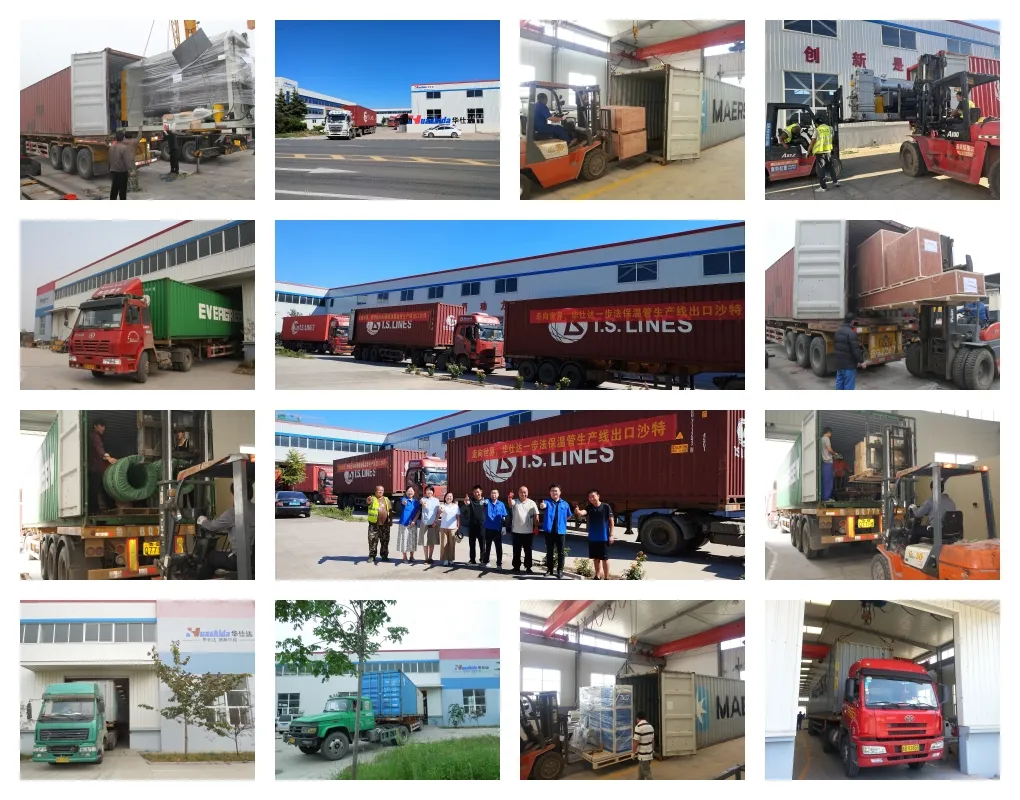

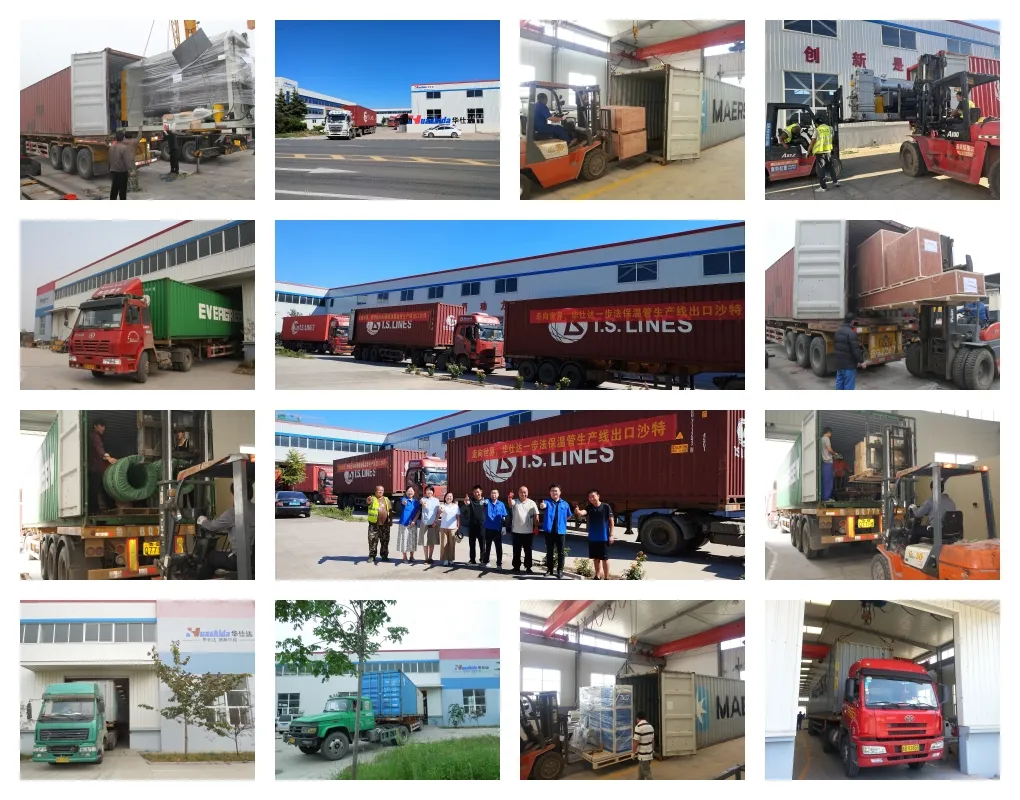

Delivery

Company Profile

Qingdao Huashida Machinery Co., Ltd. has been engaged in the development and producing of pipeline anti-corrosion equipment and raw materials since 2003. It is a leader manufacturer of heat-shrinkable sleeve and equipment in China. Huashida brand is favored by domestic and foreign customers. Devices of the equipment design have our patents. We passed ISO9001, ISO14001Environment, ISO45001 health certification. Up to now, more than 500 sets of production lines have been exported to Russia, Kazakhstan, Belarus, Egypt, Iran, Indonesia and other countries. Huashida brand heat shrinkable sleeve equipment in the production process of continuous summary and update has launched the fourth generation of products. The whole production line has reasonable design, intelligent operation, high speed and high efficiency, energy saving and electricity saving material labor cost. Continuous improvement in component design ensures uniform thickness, improved shrinkage, tensile strength and elongation at break. Product quality to meet the needs of different pipeline anti-corrosion demand. We have a professional after-sales service team to provide on-site and online video teaching and training. Help customers solve production problems as soon as possible.

Our Team

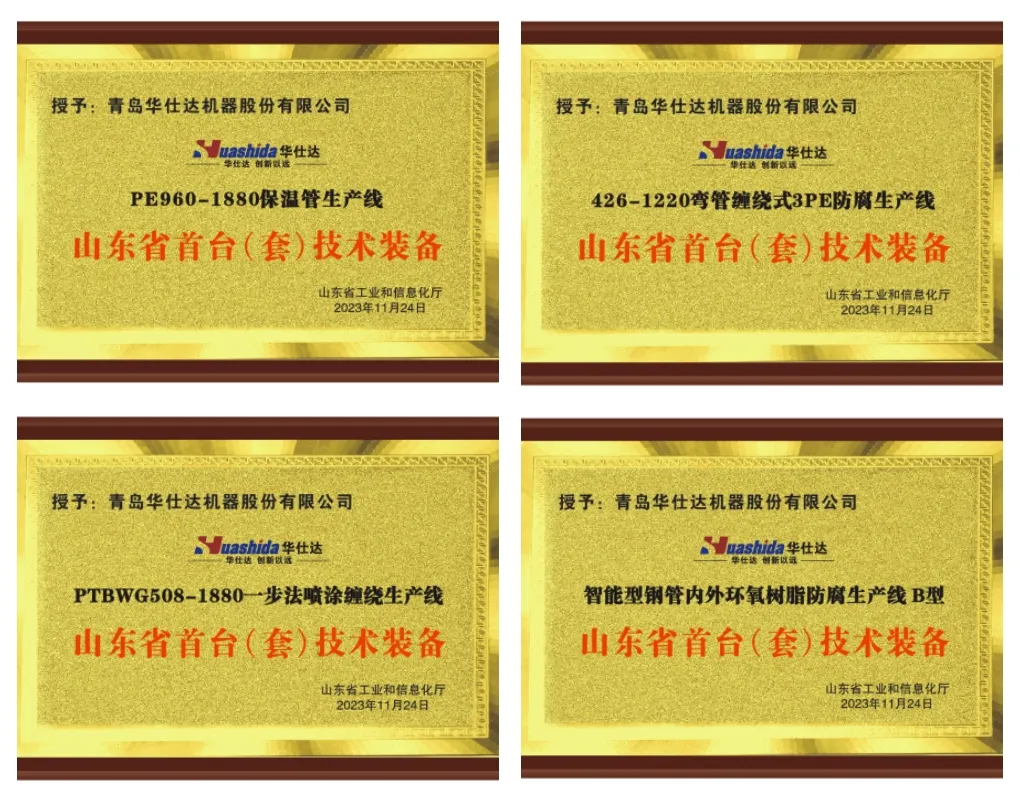

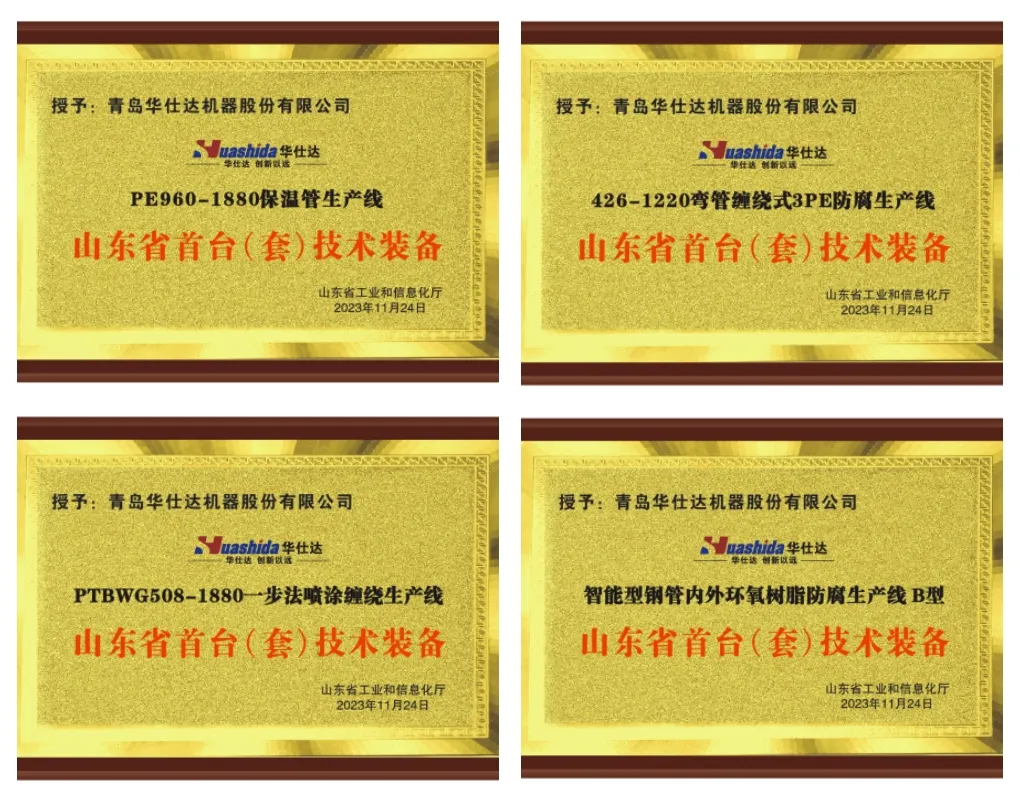

Certifications

International Trading show

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!