Product Description

The 3PE (Three-Layer Polyethylene) coating is an advanced anti-corrosion system consisting of fusion-bonded epoxy (FBE) as the inner layer, adhesive (AD) as the bonding middle layer, and polyethylene (PE) as the protective outer layer.

This multi-layer structure provides excellent mechanical strength, superior electrical insulation, stable processing performance, and environmental sustainability, making it ideal for oil and gas pipelines, urban water supply, and district heating networks.

Technological processes

Pipe Loading → Conveying → Shot Blasting (Rust Removal) → Induction Heating → FBE Coating → AD & PE Extrusion Coating → Water Cooling → Conveying → Pipe End Grinding → Unloading

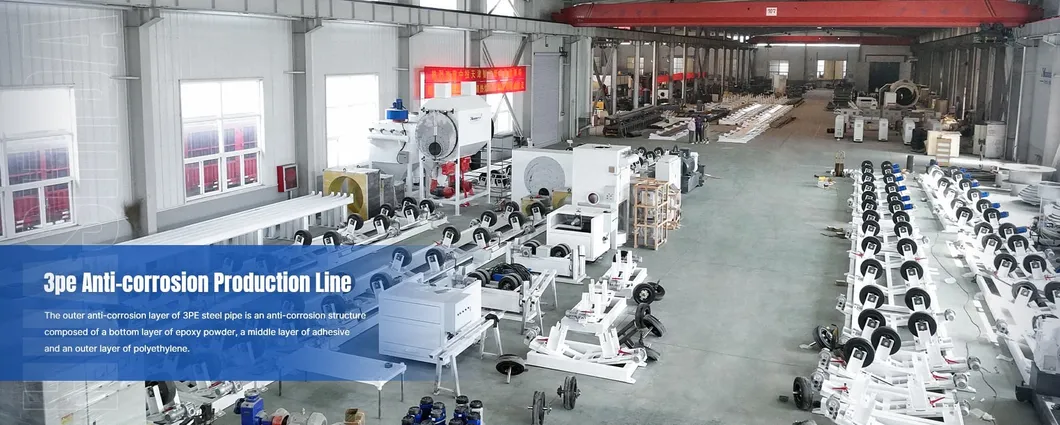

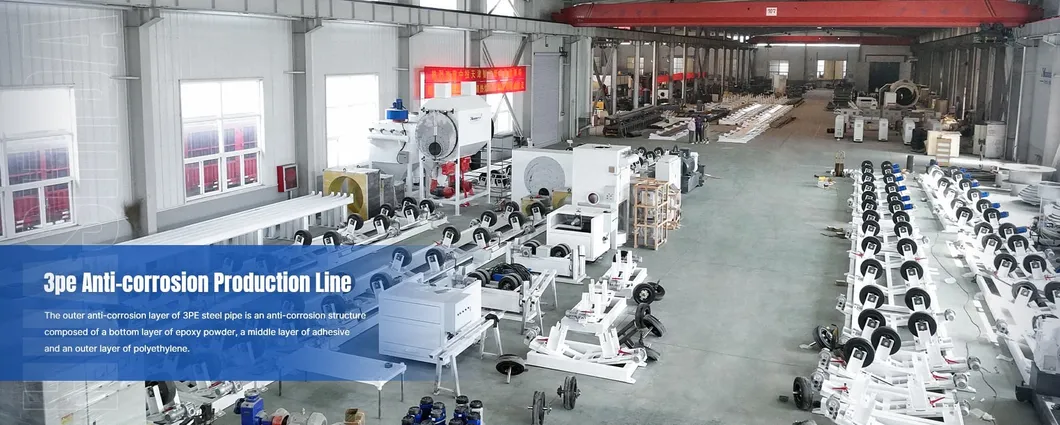

Main Equipment Composition

Surface Treatment: Shot blasting machine, cyclone dust collector, pulse dust remover

Heating System: Induction heating equipment

Coating System: FBE powder coating unit, adhesive extruder, PE extruder

Cooling System: Water spraying and cooling device

Conveying System: Pipe loading/unloading platform, turning rollers

Control System: PLC automatic control system

Auxiliary Equipment: PE beveling machine, hydraulic lifting system, exhaust & ventilation system

Our Advantages

Cost Reduction - High sealing performance, energy-saving, and environmentally friendly.

Long Service Life - Easy installation and construction, lifespan up to 30-50 years.

Excellent Impact Resistance - Performs well even under low temperatures; low water absorption.

Superior Anti-Corrosion Performance - Reliable protection with simple and economical process.

Fully Automatic Operation - PLC control with intelligent sensors for position, speed, and energy monitoring ensures precision and efficiency.

Applications

3-layer PE coated steel pipes are widely used in:

Oil and gas transmission pipelines - providing long-term protection against corrosion and external damage.

Urban gas and water supply systems - ensuring safe, clean, and reliable transport of fluids.

District heating networks - maintaining insulation and corrosion resistance under high-temperature conditions.

Underground and industrial anti-corrosion projects - offering durable protection for buried and exposed steel pipelines.

Global Application:

This advanced coating technology has been successfully applied in major infrastructure projects both domestically and internationally.

Products are exported to Europe, the Middle East, Central Asia, Africa, Russia, and other regions worldwide.

Company Profile

Qingdao Huashida Machinery Co., LTD, is a manufacturer of series of plastic pipe machines, municipal pipe machines, pipe insulation&anticorrosion machines, and pipe jointing&anticorrosion materials, with 21 years of production experience.

Our main products are:

1. HDPE jacket pipe for pre-insulated pipe Production Line (110-2000mm)

2. Rigid pre-insulated pipe Production Line

3. Flexible pre-insulated pipe(PERT) production line

4. Steel pipe FBE/2LPE/3LPE anti-corrosion coating line

5. Steel pipe derusting line

6. PE pressure pipe/Water Gas supply pipe production line

6. PP/PE plastic board/sheet/geomembrane production line

7. NBR PVC Thermal insulation tube/plate production line

8.Pipeline anti-corrosion materials and instruments: heat shrink joint coating sleeve, electro-fusion weldable joint sleeve, portable welding gun(extruder), PE PP welding rod.

We have been working with more than 400 overseas customers and exporting our products to Kazakhstan, Uzbekistan, Iran, Turkey, Russia, Nigeria and other countries.

Our team

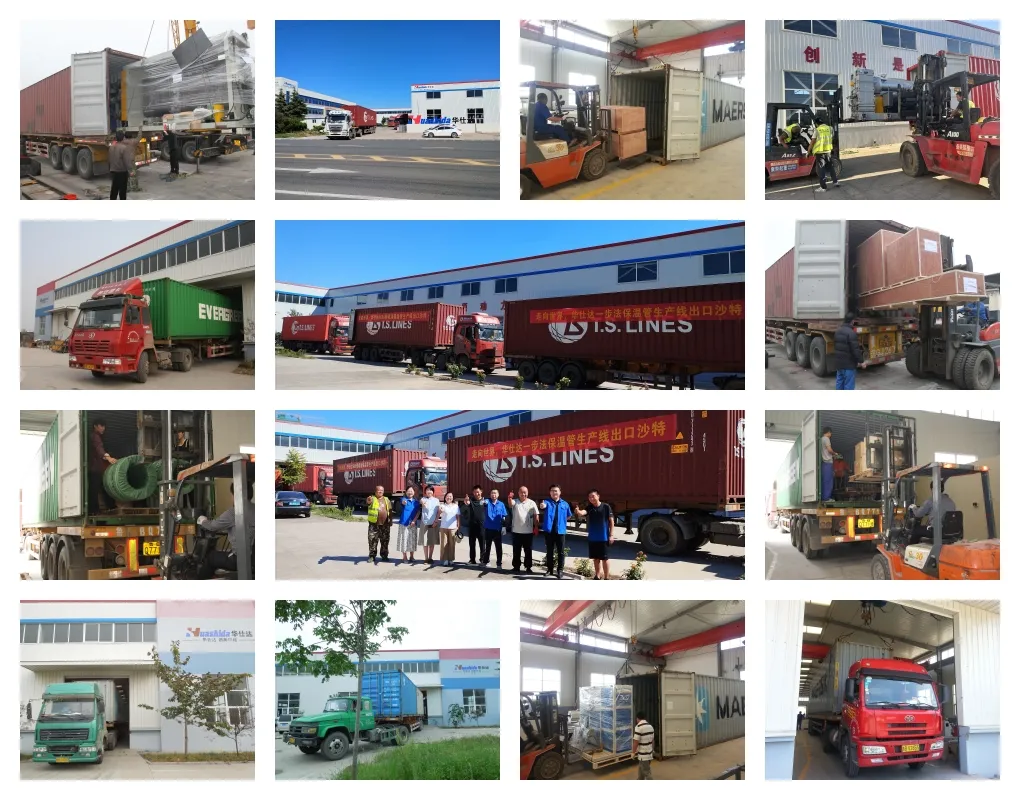

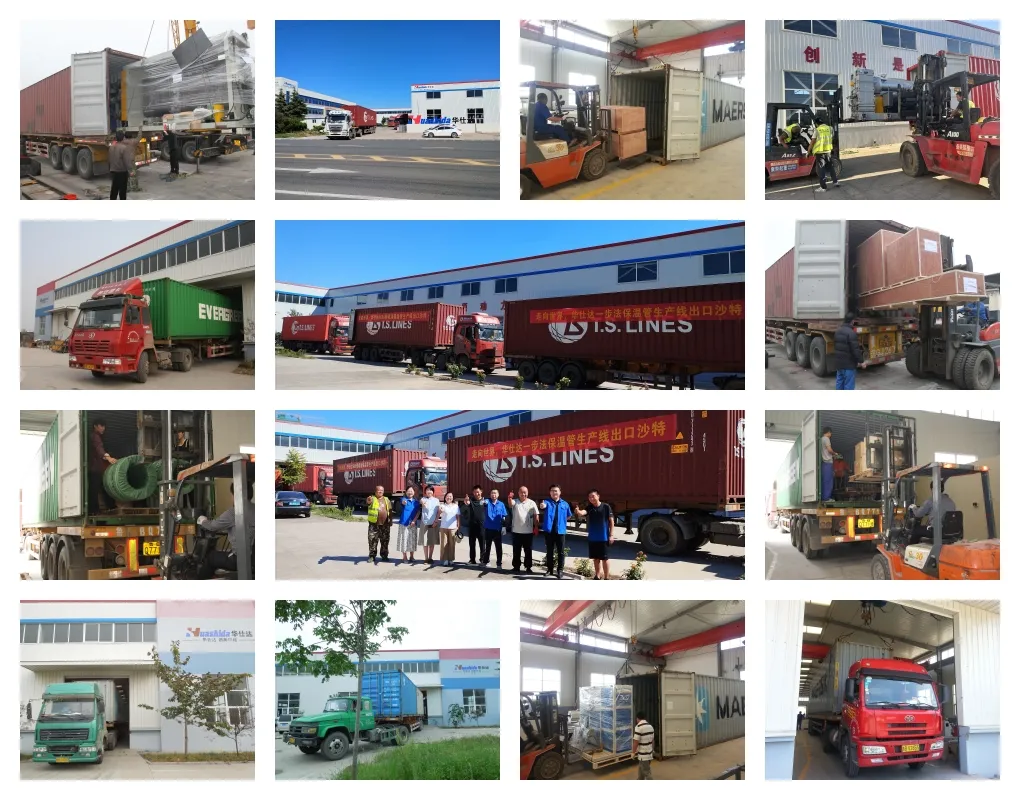

Delivery

Exhibition

Certifications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!