HDPE Heat Shrinkable Sleeve Production and Adhesive Coating Line Thickness 1.5-3.5 mm

HDPE Heat Shrinkable Sleeve Production And Adhesive Coating Line Thickness 1.5-3.5 mm

Product Description

The HSSC-1 Heat Shrinkable Sleeve (2-layer) is developed and manufactured by Qingdao Huashida Machinery Co., Ltd for pipeline anti-corrosion applications. This sleeve consists of radiation cross-linked polyethylene backing and high-shear strength melt adhesive, featuring shape memory functionality. The hot melt adhesive is pressed into the joint by the shrink force, forming a perfect seal after heating. The HSSC-1 sleeve is compatible with standard pipe coatings, and is ideal for use with bare pipes, replacement pipe sections, and large-radius bends. It is particularly suited for large-diameter wastewater pipes, requiring minimal preheating during installation.

In addition, we also offer a three-layer reinforced heat shrinkable sleeve, which is composed of three layers of material designed to enhance the sleeve's durability, protective capacity, and anti-corrosion properties. The middle mesh layer is typically a reinforced mesh (subject to customer requirements), and its main function is to enhance the mechanical strength and tensile resistance of the heat shrinkable sleeve.

Buried Pipeline Field Joint Heat Shrinkable Sleeve is made by PE/PP material, used for oil/gas/water pipeline anticorrosion joints. It is served for 3LPE/PP pipeline, pre-insulation pipe end seal, and hdpe corrugated pipe.

Application fields

Application area:

It is mainly used for wrapping around pipe, anti-corrosion of kinds of pipe joints, and repairing pipes.

For example: Oil and gas pipe, PU insulation pipe, 3PE/2PE steel pipe.

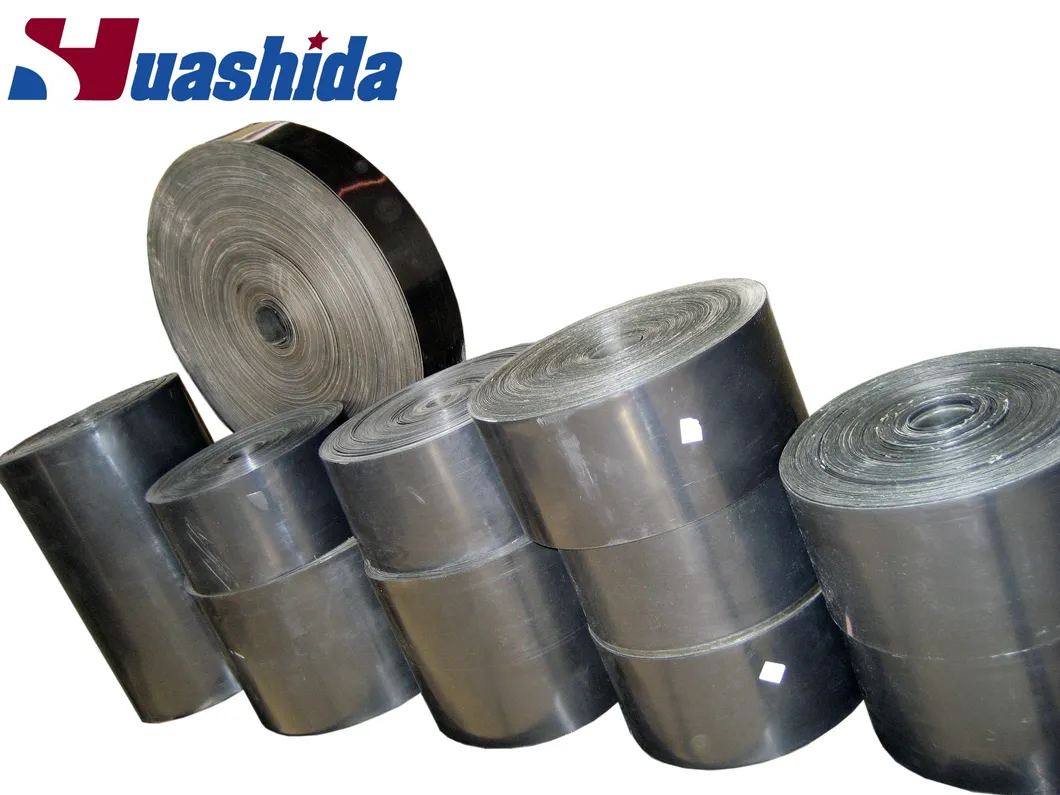

Available Products

- Pre-Cut Sleeve and Separate Closure Patch

- Pre-Cut Sleeve with Pre-Attached Closure Patch

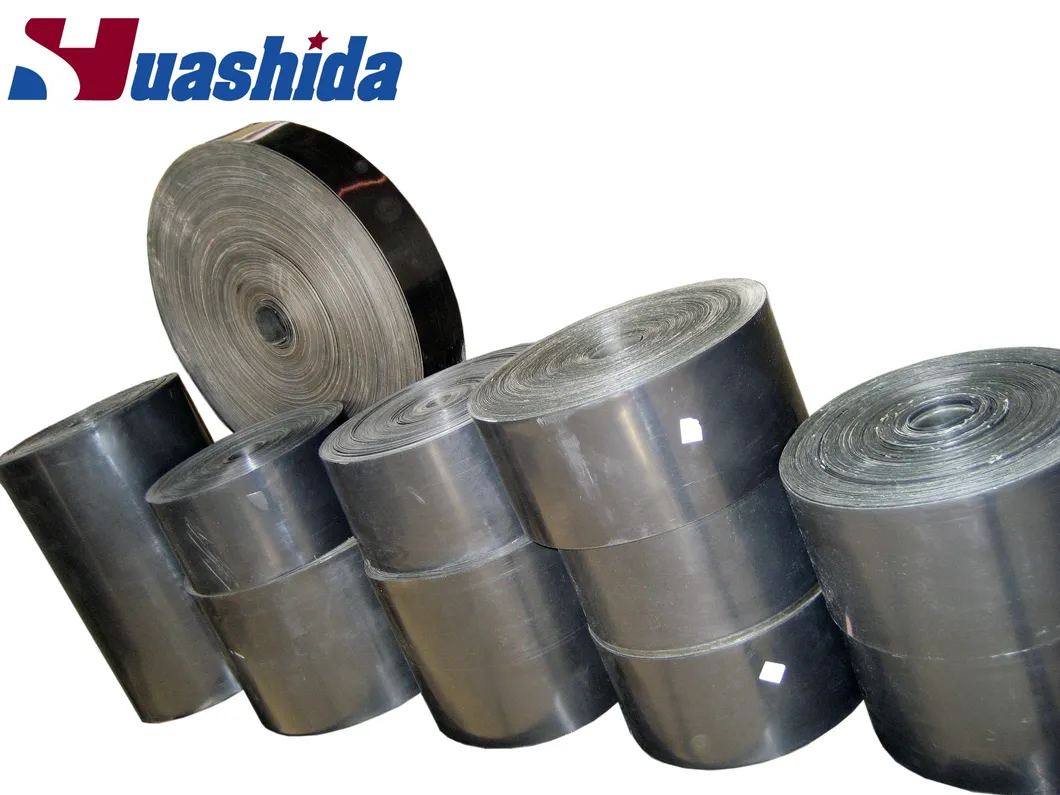

- Tape in Roll (Closure Patch to be Ordered Separately)

CONSTRUCTION CASE

Heat shrinkable sleeve for Oil & Gas Pipe

Heat shrinkable sleeve for Thermo Insulated Pipe

COMPARISIONS

3Layer Fiber reinforced heat shrink sleeve for HDD under ground pipes

3Layer Fiber reinforced PE heat shrinkable tape (sleeve) is composed of cross-linked polyethylene back, a middle layer of fiber and special heat melt adhesive an. The 3 layer reinforced sleeve gives better shrink ratio, and better strength. It is resistant to corrosion, wear, impact, UV and aging, easier to be operated.

TECHNICAL PARAMETERS

| NO |

Text Item |

Unit |

Performance |

Text Result |

Text Metho |

| Back Material |

| 1 |

Tensile Strengt |

MPa |

≥17 |

19.47 |

ASTM D638 |

| 2 |

Elongatio |

% |

≥400 |

626 |

ASTM D638 |

| 3 |

Vicat Softening Poin |

ºC |

≥90 |

92 |

ASTM D1525 |

| 4 |

Brittleness Temperatur |

ºC |

<-65 |

<-65 |

ASTM D2671C |

| 5 |

Dielectric Strengt |

MV/m |

≥25 |

33.13 |

ASTM D149 |

| 6 |

Volume Resistivit |

Ω.m |

≥1*1013 |

1.1*1013 |

ASTM D257 |

| 7 |

Environment Stress Crac |

h |

≥1000 |

>1000 |

GB/T1842 |

8 |

Chemical

resistance

(7d |

10%

HCI |

Tensile strength |

MPa |

≥85 |

104.9 |

ASTM D638 |

| Elongation |

% |

≥85 |

96.3 |

ASTM D638 |

10%

NaAH |

Tensile strength |

MPa |

≥85 |

102.1 |

ASTM D638 |

| Elongation |

% |

≥85 |

95.6 |

ASTM D638 |

10%

NaCL |

Tensile strength |

MPa |

≥85 |

108.3 |

ASTM D638 |

| Elongation |

% |

≥85 |

94.1 |

ASTM D638 |

| 9 |

Thermal aging

(150ºC,168h |

Tensile strength |

MPa |

≥14 |

20.7 |

ASTM D638 |

| Elongation |

% |

≥300 |

630 |

ASTM D638 |

| NO. |

Text Ite |

Uni |

Performanc |

Text Resul |

Text Metho |

| Adhesive |

| 1 |

Softening Poin |

ºC |

≥90 |

90.1 |

ASTM E28 |

| 2 |

Brittleness Temperatur |

ºC |

<-15 |

<-15 |

ASTM D2671C |

| 3 |

Lap Shea |

MPa |

≥1.0 |

1.5 |

ASTM D1002 |

4 |

Peel Strength

(23±2ºC |

Steel |

N/cm |

≥70 |

145.6 |

ASTM D1000 |

| Primer |

N/cm |

≥70 |

205.9 |

ASTM D1000 |

| PE laye |

N/cm |

≥70 |

190.0 |

ASTM D1000 |

| Non-solvent Epoxy Primer |

| 5 |

Shear of cured primer |

MPa |

≥5.0 |

12 |

SY/T0041 |

Packaging & Shipping

Product introduction

PE backed heat shrinkable wraparound sleeve (HSS) for pipeline is composed of radiation cross-linked polyethylene backing and special heat melt adhesive.

There is also a reinforced type, in which a glass fiber reinforced layer is added to the backing for better effect.

When heating the heat shrink sleeve, the PE backing shrinks and the adhesive melts. The sleeve closely wraps around the pipe. The heat shrinkable sleeve (HSS) forms a firm and continuous anti-corrosion body, which is resistant to corrosion, wear, impact, UV and aging.

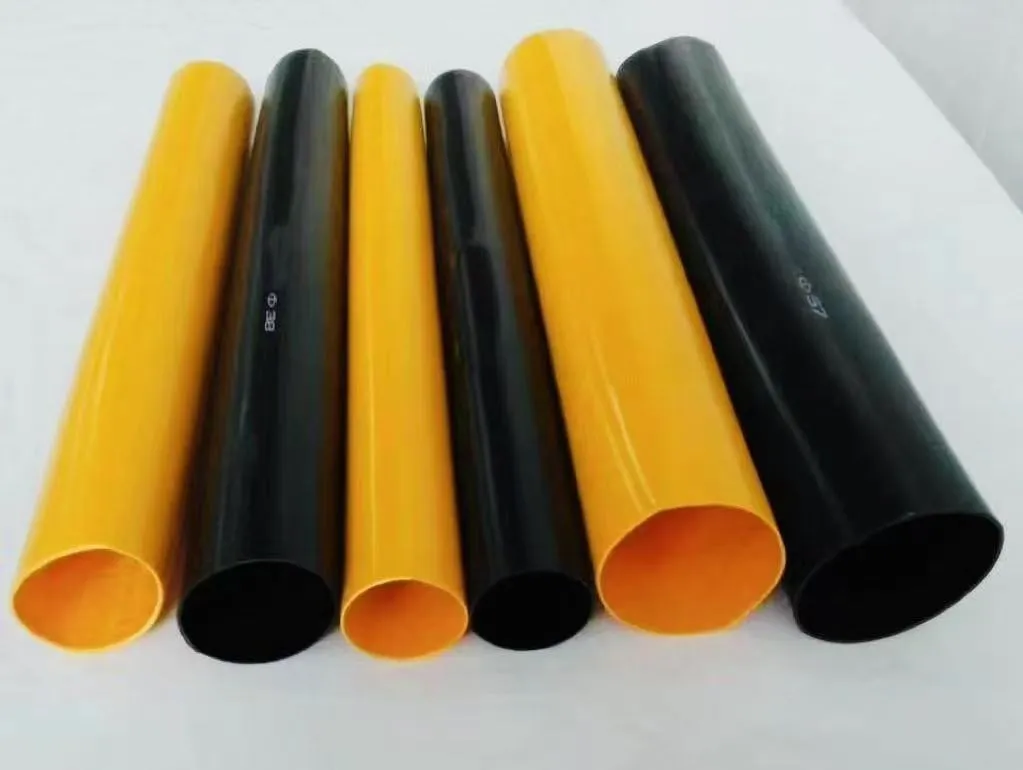

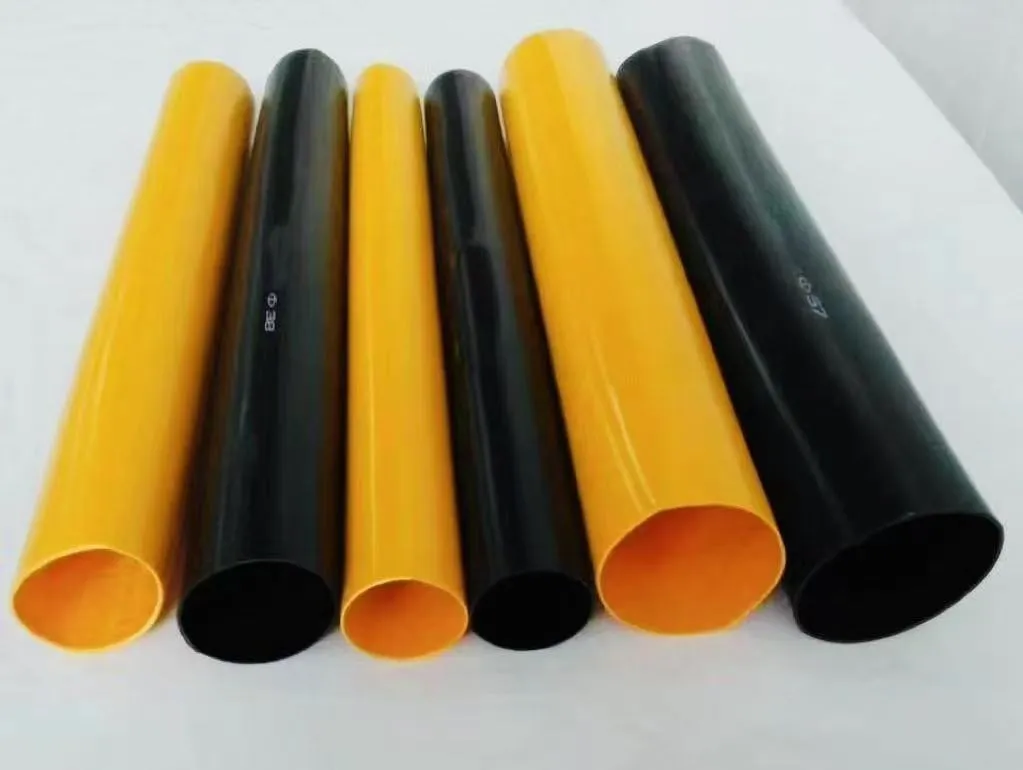

Detailed Photos

Application:

1. Field joint corrosion protection for gas oil steel pipeline, water supply pipeline.

2.Corrosion protection pipes, bends, fittings of pipeline.

3.Anti-corrosion and seal for heating pipeline

4.Connecting and seal for corrugate pipes (sewage pipe, waste pipe, drain pipe).

Feature of our heat shrinkable sleeve:

1.Fast shrinkage speed

2.Good waterproof performance

3 Good anti-corrosive performance

4.Long service life

5.High-quality PE material and adhesive

Executive Standard

Products comply with national and international standards GB/T23257-2009, SY/T4054-2003, EN12068, DIN30672 etc.

Ordering information

·pre-cut sleeve and separate closure patch

·pre-cut sleeve and separate closure patch

·tubular sleeve

·tape in roll (closure patch to be ordered separately)

The reinforced type:

CONSTRUCTION CASE

Heat shrinkable sleeve for Oil & Gas Pipe

Heat shrinkable sleeve for sealing thermo-Insulated Pipe

Product Parameters

Specification of heat shrinkable sleeve for field joint coating underground buried steel pipe

| No. |

Size, mm |

Length, mm |

Patch |

| Length, mm |

Width, mm |

| 1 |

Ф159*500 |

670 |

500 |

80 |

| 2 |

Ф219*500 |

860 |

100 |

| 3 |

Ф273*500 |

1000 |

100 |

| 4 |

Ф325*500 |

1200 |

100 |

| 5 |

Ф355*500 |

1300 |

100 |

| 6 |

Ф406*500 |

1460 |

120 |

| 7 |

Ф508*500 |

1800 |

120 |

| 8 |

Ф610*500 |

2170 |

120 |

| 9 |

Ф711*500 |

2500 |

150 |

| 10 |

Ф813*500 |

2880 |

150 |

| 11 |

Ф1016*500 |

3480 |

150 |

| 12 |

Ф1219*500 |

4120 |

200 |

| 13 |

Ф1420*500 |

4780 |

200 |

TECHNICAL PARAMETERS

| NO |

Test Item |

Unit |

Performance |

Test Result |

Test Method |

| Back Material |

| 1 |

Tensile Strength |

MPa |

≥17 |

19.47 |

ASTM D638 |

| 2 |

Elongation |

% |

≥400 |

626 |

ASTM D638 |

| 3 |

Vicat Softening Point |

ºC |

≥90 |

92 |

ASTM D1525 |

| 4 |

Brittleness Temperature |

ºC |

<-65 |

<-65 |

ASTM D2671C |

| 5 |

Dielectric Strength |

MV/m |

≥25 |

33.13 |

ASTM D149 |

| 6 |

Volume Resistivity |

Ω.m |

≥1*1013 |

1.1*1013 |

ASTM D257 |

| 7 |

Environment Stress Crack |

h |

≥1000 |

>1000 |

GB/T1842 |

8 |

Chemical

resistance

|

10%

HCI |

Tensile strength |

MPa |

≥85 |

104.9 |

ASTM D638 |

| Elongation |

% |

≥85 |

96.3 |

ASTM D638 |

10%

NaAH |

Tensile strength |

MPa |

≥85 |

102.1 |

ASTM D638 |

| Elongation |

% |

≥85 |

95.6 |

ASTM D638 |

10%

NaCL |

Tensile strength |

MPa |

≥85 |

108.3 |

ASTM D638 |

| Elongation |

% |

≥85 |

94.1 |

ASTM D638 |

| 9 |

Thermal aging

(150ºC,168h) |

Tensile strength |

MPa |

≥14 |

20.7 |

ASTM D638 |

| Elongation |

% |

≥300 |

630 |

ASTM D638 |

| NO. |

Text Item |

Uni |

Performance |

Text Result |

Text Method |

| Adhesive |

| 1 |

Softening Point |

ºC |

≥90 |

90.1 |

ASTM E28 |

| 2 |

Brittleness Temperature |

ºC |

<-15 |

<-15 |

ASTM D2671C |

| 3 |

Lap Shear |

MPa |

≥1.0 |

1.5 |

ASTM D1002 |

4 |

Peel Strength

(23±2ºC |

Steel |

N/cm |

≥70 |

145.6 |

ASTM D1000 |

| Primer |

N/cm |

≥70 |

205.9 |

ASTM D1000 |

| PE layer |

N/cm |

≥70 |

190.0 |

ASTM D1000 |

| Non-solvent Epoxy Primer |

| 5 |

Shear of cured primer |

MPa |

≥5.0 |

12 |

SY/T0041 |

Workshop

Our Advantages

Customer visiting

We are also producing machine of heat shrinkable sleeve, You are welcom to ask for more information.

Welcome to visit our factory!

We are also producing machine of heat shrinkable sleeve, You are welcom to ask for more information.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!