3lpe Fbe Pipe Poroduction Line Petroleum/Natural Gas/Water Pipeline Anticorrosion Coating

The epoxy powder coating method for the inside and outside of steel pipes is an efficient solution for anti-corrosion. This technique provides several advantages, including strong corrosion resistance, allowing the coating to withstand the erosion from various chemical agents. Additionally, the smooth surface of the coating reduces friction resistance, enhancing flow efficiency.

Due to these properties, anti-corrosive steel pipes are widely utilized in various applications, such as petroleum and natural gas transmission pipelines, water supply and drainage systems, and many other industrial fields. Their robust performance makes them an ideal choice for demanding environments, ensuring longevity and reliability in critical operations.

Application of FBE Powder Coating

Overview

The Steel Pipe Internal & External FBE Powder Coating process involves blasting both the internal and external walls of steel pipes, followed by the application of FBE epoxy powder coating. This process is particularly suited for water supply applications in civil use.

Coating Structure

-

Internal Wall Blasting: Prepares the surface by removing contaminants and enhancing adhesion.

-

External Wall Blasting: Similar preparation for the outer surface, ensuring a strong bond with the coating.

-

FBE Epoxy Powder Coating: Applied to create a protective layer that offers excellent corrosion resistance.

Properties of Epoxy Powder Coating

- Thermosetting Non-Toxic Coating: Upon solidification, it forms a high molecular weight cross-linking structure, enhancing durability.

- Chemical Anticorrosion: Provides strong resistance against various corrosive substances.

- Higher Mechanical Properties: Ensures improved strength and resilience.

Layer Functions

This advanced coating system effectively protects steel pipes used in water supply, significantly extending their service life and performance.

Main equipment:

| Item |

Process Flow |

| 1 |

Upload pipes |

| 2 |

pipes sprial conveyor |

| 3 |

external blasting |

| 4 |

internal blasting |

| 5 |

Rust removal |

| 6 |

intermediate frequency heating |

| 7 |

FBE powder coating |

| 8 |

Powder recycling system |

| 9 |

load down pipe rack |

Detailed Photos

We also can make External 3LPE internal FEB powder coating Line

Our Advantages

-Adopt advanced technology

-Stable operation

-High degree of automation, saving labor costs

-Good anti-corrosion quality, meets international standard

-Supply full completed production solution: design, installation, commissioning,training

-Share you 389 sets of production experience from all the world

-Having 9 professional senior engineers

-Having a high-end plastic machinery equipment expert workstation in China

FAQ

Question & Answer

Q1: What is the size of the pipe diameter your equipment can produce?

A: We can produce steel pipes in the following models:

- 48-219 mm

- 219-1220 mm

- 325-1600 mm

- 508-2400 mm

- 1000-3200 mm

Q2. What is Descaling grade?

A:SA2.5?

Q3. What is your anticorrosion coating standard?

A: It can meet SY/T0413-2002 ,GB/T23257-2009, German DIN 30670 , DIN 30678 and coating specification requirements from American Corrosion Association, and DNV . The product pipe fully complies with SY/T0315-2005 ,CNPC38-2002 "Technical specifications for double-layer fusion-bonded epoxy powder coating on buried steel pipe and Canada, American Corrosion Association standards.

Q4. What is Delivery Time

A: 2-3monthes after deposit.

Q5. Production output:

A: It is different output capability as different pipe diameter, the Max. is 3 to 8 km/day, and annual processing capacity is 2 million square meters (Φ508 mm).

Q6. Coating thickness:

A: 80~800um

Q7. Which country did you sell your 3PE equipment?

A. We have produced nearly 50sets 3PE processing line at home and abroad. Such as Russia, Iran, UAE, Iran, India, Belarus, Kazakhstan and so on.

Q8. After-sales service:

A: Warranty period:

Before delivery all the equipment must be trial operated to confirm the quantity perfectly.

The warranty period is 12 months from the date of pick-up for mechanical part , and 6 months for the electrical part. The seller provides free technical services and provides training and guidance to buyer operators.

Company Profile

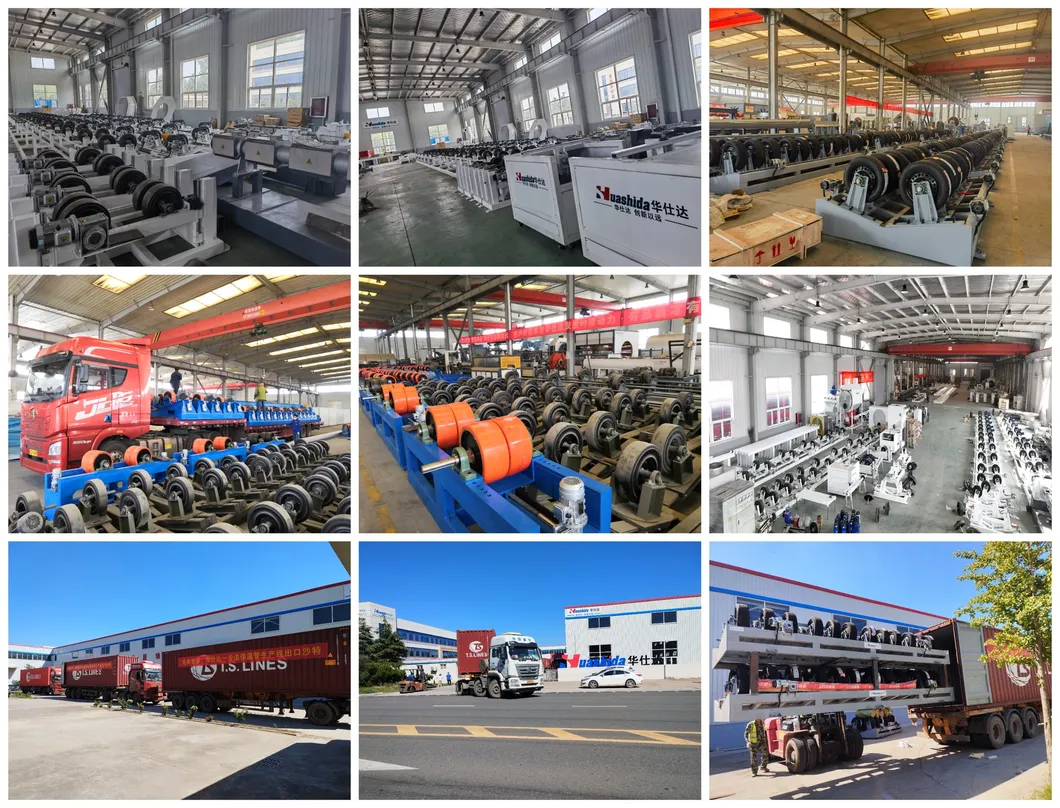

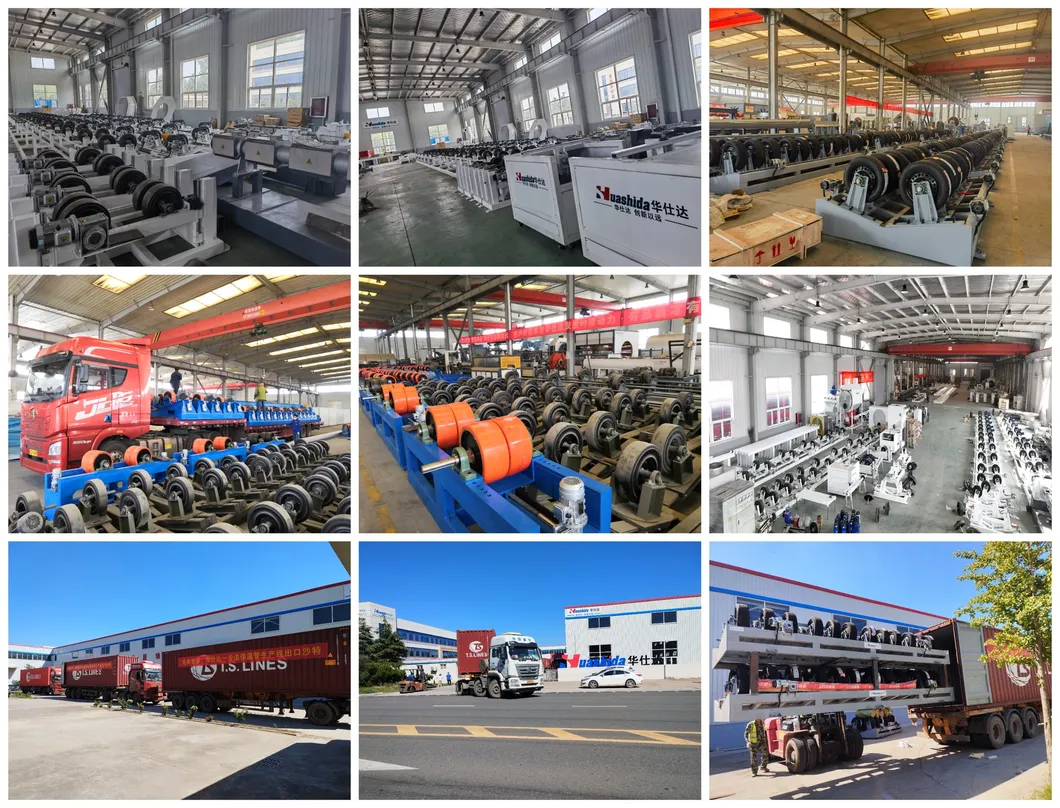

Qingdao Huashida Machinery Co., Ltd is one of the top manufacturers of plastic extrusion machines in China, specialized in dealing with Steel pipe in terms of anticorrosion and insulation technology, R&D of the coating technique, design and manufacture of the equipment for coating, products and materials, researching and development of plastic extrusion equipments, especially of Vacuum Calibrating method PE insulation jacket pipe extrusion line, and PE hollow wall spiral pipe production line, PE PP sheet extrusion line, and pipe joints and welding tools such as heat shrinkable sleeve, Electro fusion sleeve etc.

Up to now, we have successfully entered overseas markets, including Russia, Iran, UAE, India, Belarus, and Kazakhstan. Our pipeline production line consists of nearly 50 sets deployed both domestically and internationally.

The Huashida factory is located in the Qingdao High & New Technology Industrial Area, covering an area of approximately 4,000 square meters. We have obtained more than 10 patents and numerous industry certifications recognized both at home and abroad.

Huashida boasts a highly qualified and experienced team dedicated to research and design, manufacturing, and site operations. Our robust production capacity enables us to offer a diverse range of reliable products tailored to meet our customers' specific needs. Additionally, our outstanding R&D and design capabilities ensure we effectively address unique requirements. We provide timely and convenient technical support through our comprehensive after-sales service system.

International Trading show

Clients case

Certifications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!