Water Supply 3LPE / FBE / VUS Anti-Corrosion Insulation Coating Production Equipment Pipeline

Product Description

A steel pipe anti - corrosion coating line is utilized in the factory to apply anti - corrosion coatings to steel pipes of various diameters. These coated pipes are more extensively employed in diverse engineering construction projects, particularly in heating, gas, and oil fields.

The lines can be applied to FBE, 2 layer FBE, 2 layer PE, 2 layer PP and 3 layer PE anti-corrosion coating.

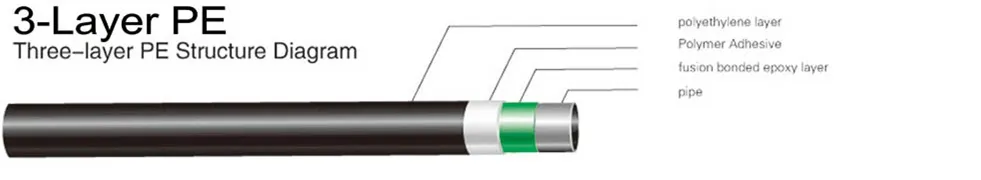

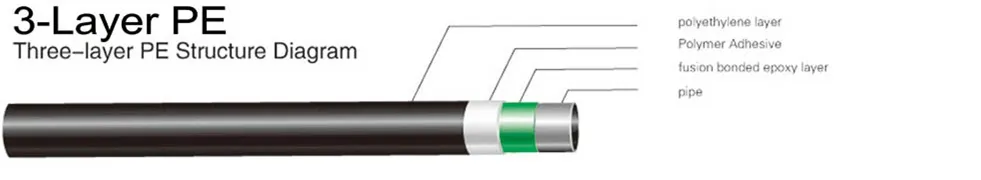

3 layer PE anti-corrosion coating consists of first FBE coating, middle adhesive layer and outer polyethylene layer.

Steel pipe 3LPE anti-corrosion coating line

(Dia. 159-4200mm)

Steel pipe internal external FBE coating line

(Dia. 500-4200mm)

Internal FBE external 3LPE coating line

(Dia. 159-4200mm)

Small size steel pipe O-type extrusion 3LPE coating line

(Dia. 57-426mm)

Steel Bend pipe FBE &3LPE coating Production Line

Application

The three-layer polyethylene anti-corrosion coating represents a state-of-the-art technique for serving as the external protective layer of buried pipes. It finds extensive application in safeguarding gas and oil transmission pipelines, urban gas supply systems, water supply pipes, and other conduits for fluid transportation. This 3-layer PE anti-corrosion coating is capable of enhancing the pipeline's mechanical attributes while offering high electrical resistivity, water resistance, abrasion resistance, and anti-aging capabilities.

Detailed Photos

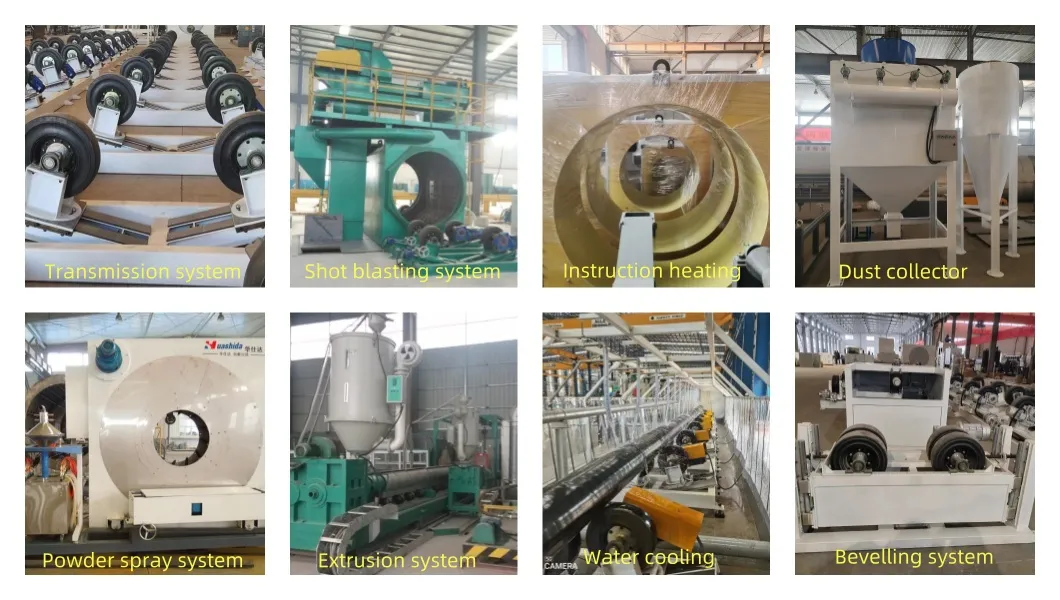

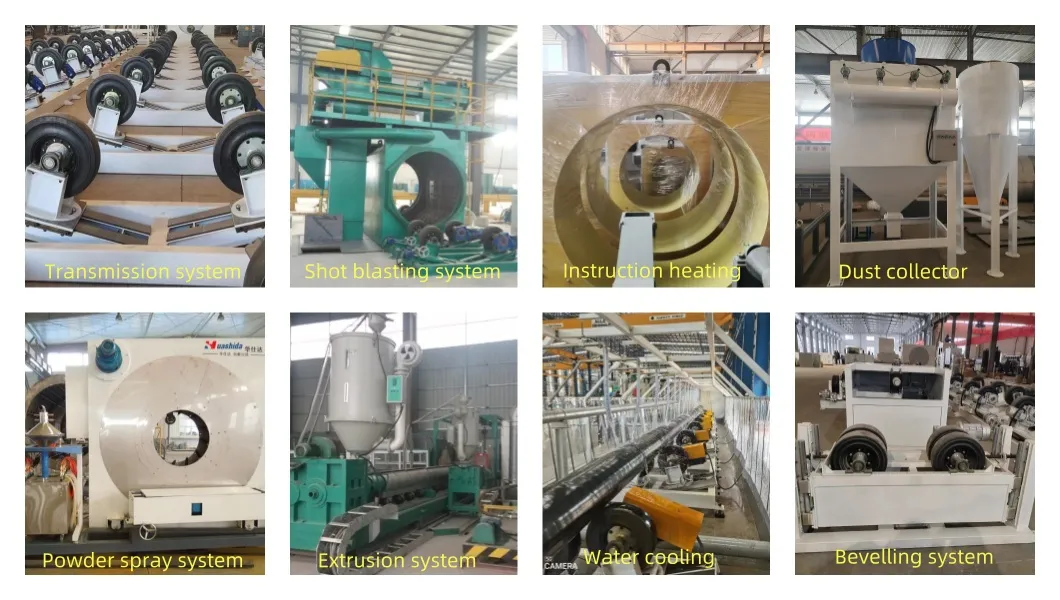

The anti-corrosion coating processing line includes:

-steel pipe transmission system

-surface treatment system

-pipe dust removal system

-pipe heating system

-electrostatic spraying system

-coating system

-water cooling system

-end cutting system

-hydraulic and pneumatic system

-testing system

-electronic control system.

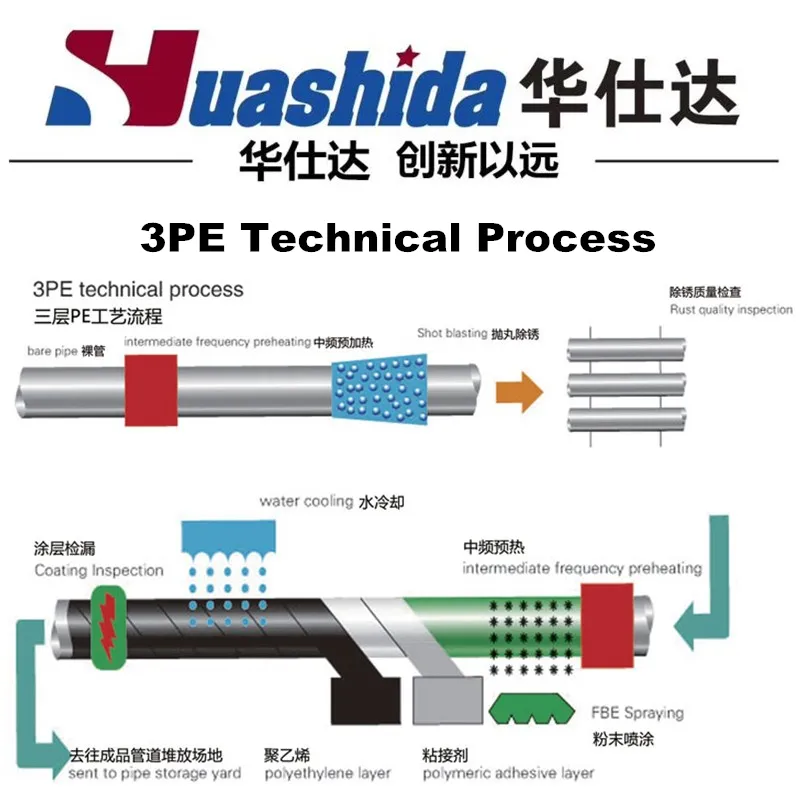

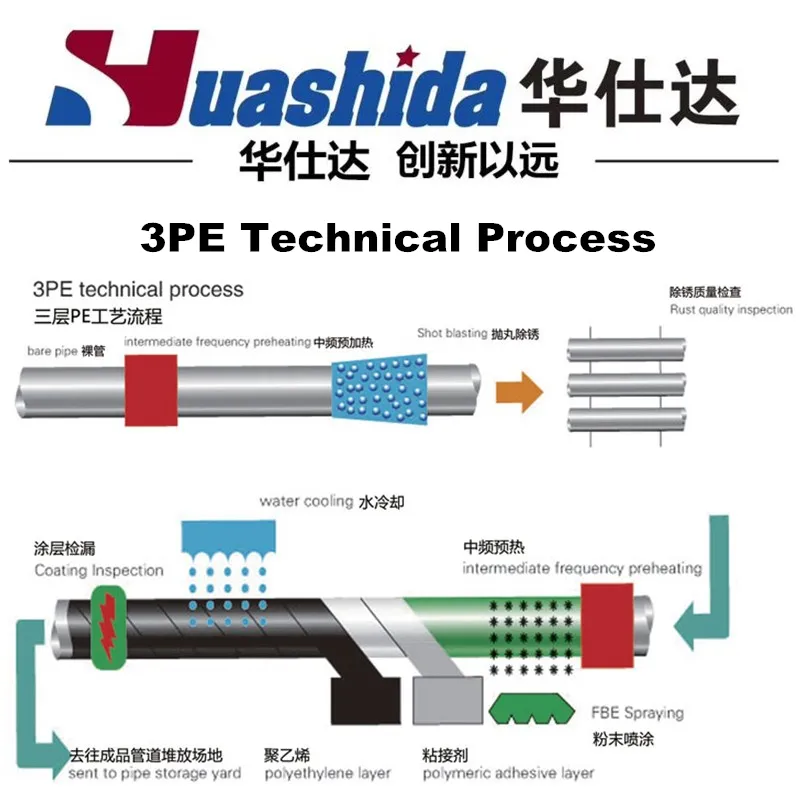

Technological processes

Upload pipes→pipes screw conveyor→rust removal → intermediate frequency heating→Epoxy powder coating→outer layer adhesive polyethylene coating→cooling spray→pipes screw conveyor→grinding pipe ends→dowload pipes

Our Advantages

-Adopt advanced technology

-Stable operation

-High degree of automation, saving labor costs

-Good anti-corrosion quality, meets international standard

-Supply full completed production solution: design, installation, commissioning,training

-Share you 389 sets of production experience from all the world

-Having 9 professional senior engineers

-Having a high-end plastic machinery equipment expert workstation in China

Main Equipment List

| No. |

Name |

Set |

| A. Derusting Equipment |

| 1 |

Pipe wheel conveyor |

1 |

| 2 |

Shot Blasting Machine |

1 |

| 3 |

Cyclone Dust Collector |

1 |

| 4 |

Pulse dust collector |

1 |

| 5 |

Centrifugal exhaust fan |

1 |

| 6 |

Rust removal equipment PLC |

1 |

| B. Coating equipment |

| 1 |

Pipe wheel conveyor |

1 |

| 2 |

Induction heating device |

1 |

| 3 |

Powder spraying device |

1 |

| 4 |

Automatic loading dryer |

2 |

| 5 |

SJ-65/30 Extruder |

1 |

| 6 |

SJ-120/30 Extruder |

1 |

| 7 |

Hot melt adhesive extruder die |

1 |

| 8 |

PE sheet extruder head mold |

1 |

| 9 |

Hot melt adhesive/PE sheet coating device |

1 |

| 10 |

Environmental Protection Ventilation equipment |

1 |

| 11 |

Cooling Spray equipment |

1 |

| C.Platform Equipment |

| 1 |

Steel pipe uploading platform |

1 |

| 2 |

Downloading platform |

1 |

| 3 |

Pipe storage platform |

1 |

| 4 |

Turnover machanism |

3 |

| D.Groove Equipment |

| 1 |

PE Beveling Machine |

2 |

| 2 |

Hydraulic Lifting and Turning Machinery |

1 |

| 3 |

Hydraulic Equipment |

1 |

| 4 |

PLC automatic control system |

1 |

Product Parameters

1. Pipe diameter: 50-4200mm

2. Processing capacity: ≥250m2/h

3. Cleaning level: ≥Sa2.5

4. Materials for production: epoxy powder, adhesive, polyethylene

Customer cases

Company Profile

Qingdao Huashida Machinery Co., LTD, is a manufacturer of series of plastic pipe machines, municipal pipe machines, pipe insulation&anticorrosion machines, and pipe jointing&anticorrosion materials, with 21 years of production experience.

Our main products are:

1. HDPE jacket pipe for pre-insulated pipe Production Line (110-2000mm)

2. Rigid pre-insulated pipe Production Line

3. Flexible pre-insulated pipe(PERT) production line

4. Steel pipe FBE/2LPE/3LPE anti-corrosion coating line

5. Steel pipe derusting line

6. PE pressure pipe/Water Gas supply pipe production line

6. PP/PE plastic board/sheet/geomembrane production line

7. NBR PVC Thermal insulation tube/plate production line

8.Pipeline anti-corrosion materials and instruments: heat shrink joint coating sleeve, electro-fusion weldable joint sleeve, portable welding gun(extruder), PE PP welding rod.

We have been working with more than 400 overseas customers and exporting our products to Kazakhstan, Uzbekistan, Iran, Turkey, Russia, Nigeria and other countries.

Our team

Delivery

Exhibition

Certifications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!