Description

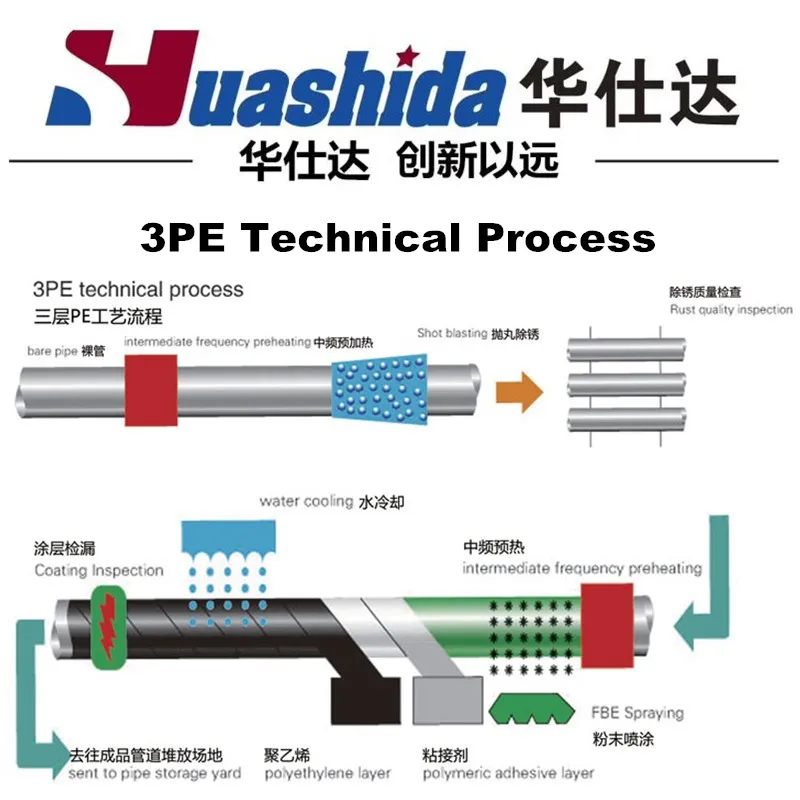

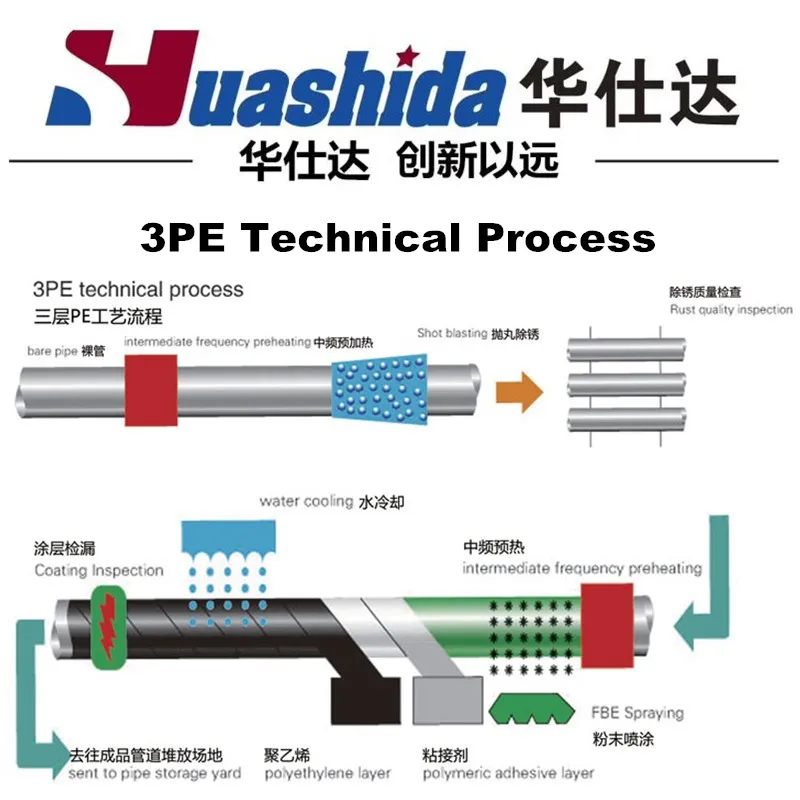

3PE Anticorrosion coating processing line is to make 3 layer anti-corrosion coating for kinds of steel pipes.

3 layer coatings, first FBE coating, middle is adhesive layer, outside polyethylene layer.

3PE can strengthen the pipeline's mechanical properties, high electrical resistance, waterproof, wearable, anti-aging.

3PE coating/coated steel pipes are widely used in pipeline systems for the transmission of oil, gas, water and other fluids. They have highly resistance to corrosive from chemicals, moisture, harmful environment etc.

The line includes systems of steel pipe transportation, surface disposal, dust catching, pipe heating, electrostatic spraying, coating, water cooling, edge cutting, hydraulic and pneumatic device, detecting and electric controlling system.

.

Technological processes

Upload pipes→pipes screw conveyor→rust removal of intermediate frequency heating→Epoxy powder coating→outer layer soli quid & polyethylene coating→cooling spray→pipes screw conveyor→grinding pipes, send→unload pipes

Main Equipment of 3PE anticorrosion processing

Configuration List

| No. |

Name |

Set |

| A. Derusting Equipment |

| 1 |

Pipe-converying Equipment |

1 |

| 2 |

Shot Blast Cleaning Machine |

1 |

| 3 |

Cyclone Dust Collector |

1 |

| 4 |

Pulse dust collector |

1 |

| 5 |

Centrifugal exhaust fan |

1 |

| 6 |

Rust removal equipment PLC |

1 |

| B. Coating equipment |

| 1 |

Coating transfer equipment |

1 |

| 2 |

IF heating device |

1 |

| 3 |

Powder spraying device |

1 |

| 4 |

Automatic loading dryer |

2 |

| 5 |

SJ-65/30 Extruder |

1 |

| 6 |

SJ-180/30 Extruder |

1 |

| 7 |

Hot melt adhesive extruder die |

1 |

| 8 |

PE sheet extruder head mold |

1 |

| 9 |

Hot melt adhesive/PE sheet coating device |

1 |

| 10 |

Environmental Protection Ventilation equipment |

1 |

| 11 |

Cooling Spray equipment |

1 |

| C.Platform Equipment |

| 1 |

Steel pipe platform |

1 |

| 2 |

Post-rust removal transition platform |

1 |

| 3 |

Product tube storage platform |

1 |

| 4 |

Hydraulic Equipment |

3 |

| D.Groove Equipment |

| 1 |

PE Beveling Machine |

2 |

| 2 |

Hydraulic Lifting and Turning Machinery |

1 |

| 3 |

Hydraulic Equipment |

1 |

| 4 |

PLC |

1 |

| E.Compressed air Equipment |

| 1 |

Screw Air Compressor |

1 |

| 2 |

Cold dry machine |

1 |

| 3 |

Precision filters |

3 |

| 4 |

Gas tanks |

1 |

Question & Answer:

Q1. What is the range of pipe diameter the equipment can produce?

A: Diameter of steel Pipe: 48-219mm,219-1220mm,800-1600mm,1000-2400mm

Q2. What is the sand blasting grade?

A:SA2.5

Q3. What is your anti-corrosion coating standard?

A: It can meet SY/T0413-2002 ,GB/T23257-2009, German DIN 30670 , DIN 30678 and coating specification requirements from American Corrosion Association, and DNV . The product pipe fully complies with SY/T0315-2005 ,CNPC38-2002 "Technical specifications for double-layer fusion-bonded epoxy powder coating on buried steel pipe and Canada, American Corrosion Association standards.

Q4. What is Delivery Time?

A: 2-3monthes after deposit.

Q5. Production output

A: It is different output capability as different pipe diameter, the Max. is 3 to 8 km/day, and annual processing capacity is 2 million square meters (Φ508 mm).

Q6. Coating thickness:

A: 80~800um

Q7. To which country did you sell your 3PE equipment?

A. We have produced nearly 50sets 3PE processing line at home and abroad. Such as Russia, Iran, UAE, Iran, India, Belarus, Kazakhstan and so on.

Q8. After-sales service:

A: Warranty period:

Before delivery all the equipment must be trial operated to confirm the quantity perfectly.

The warranty period is 12 months from the date of pick-up for mechanical part , and 6 months for the electrical part.

Service:

We provide technical services and provide training and guidance to buyer operators.

We have been working with more than 400 overseas customers and exporting our products to Kazakhstan, Uzbekistan, Iran, Turkey, Russia, Nigeria and other countries.

Our team

Delivery

Exhibition

Certifications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!