Automatic steel pipe bends fittings 3LPE coating line

is an advanced solution to apply 3LPE/FBE external coating on steel pipe bends, which are widely used in pipeline systems for the transmission of oil, gas, water and other fluids.They have highly resistance to corrosive from chemicals, moisture, harmful environment etc.

Winding anticorrosive steel pipe parameters

Diameter of steel pipe: 426, 630, 720, 820

Curvature radius: 4-6 times D

Elbow angle: 15-90 degrees.

Steel tube wall thickness: 8 mm -12 mm

Epoxy powder thickness: greater than 170 um

AD copolymer adhesive thickness: 170-250 um

PE layer thickness: 2.5 - 3.7 mm

Russian SPV Steel pipe company, originally a steel pipe only business, because the Russian market has a large number of anti-corrosion steel pipe demand, they decided to invest in the construction of a production line for pipeline anti-corrosion. After signing the order with Walstad last year, Walstad prepared its production equipment for shipment according to the schedule requirements.

| Steel pipe outside shot blasting derusting operation line |

| No. |

Description |

Qty. |

Remark |

| 1 |

Transmission line |

1set |

|

| 2 |

Shot blasting derusting line |

1set |

|

| 3 |

Cyclone dust collector |

1set |

|

| 4 |

Pulse filter cartridge dust collector |

1set |

|

| 5 |

Centrifugal wind blower |

1set |

|

| 6 |

Derusting equipment electrical control system |

1set

|

|

| Steel pipe outside spiral 3PE production line |

| No. |

Description |

Qty. |

|

| 1 |

Coating transmit system |

1set |

|

| 2 |

Intermediate frequency heating system |

1set |

|

| 3 |

Epoxy spraying system |

1set |

|

| 4 |

Automatic feeding dryer |

2sets |

|

| 5 |

single screw high efficiency extruder SJ-65/30 |

1set

|

|

| 6 |

SJ-120/30 extruder |

1set |

|

| 7 |

Hot melt adhesive extrusion die head |

1set |

|

| 8 |

PE sheet extrusion die head |

1set |

|

| 9 |

Hot melt adhesive/PE sheet press device |

1set |

|

| 10 |

Stainless steel spray powder chamber |

1set |

|

| 11 |

Cooling water spray system |

1set |

|

| Platform system |

| No. |

Description |

Qty. |

|

| 1 |

Steel pipe up load platform |

1set |

|

| 2 |

Derusting transition platform |

1set |

|

| 3 |

Finished pipe storage system |

1set |

|

| 4 |

Hydraulic system |

3sets |

|

| Grooving system |

| No. |

Description |

Qty. |

|

| 1 |

PE grooving device |

2sets |

|

| 2 |

Hydraulic elevating pipe turner |

2sets |

|

| 3 |

Operating cabinet |

1set |

|

Overall dimension: 20 m X 15 m

Installed power:450 kw

Water: 30 m3

Compressed air: 6 m3/ min.

Temperature: ≥5℃

Pipe diameter range: 400-1220mm

Radius: 4-6D

Angle: 15-90 degrees.

Wall thickness: 8 mm -40mm

Epoxy powder thickness: ≥170 um

Adhesive thickness: 170-250 um

PE layer thickness: 2.5 - 3.7mm

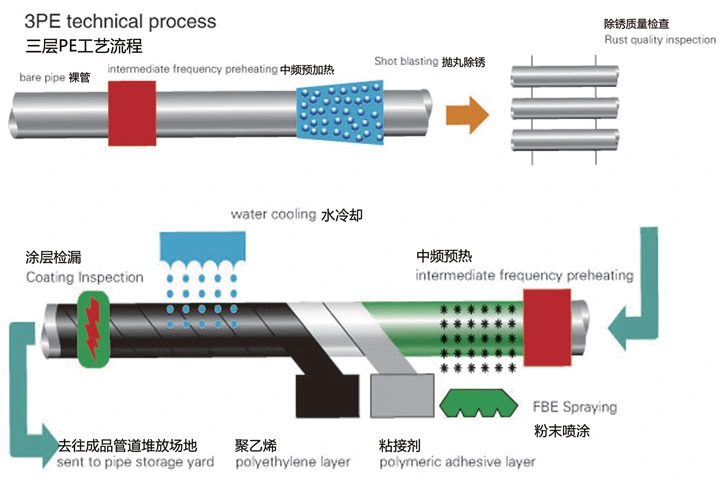

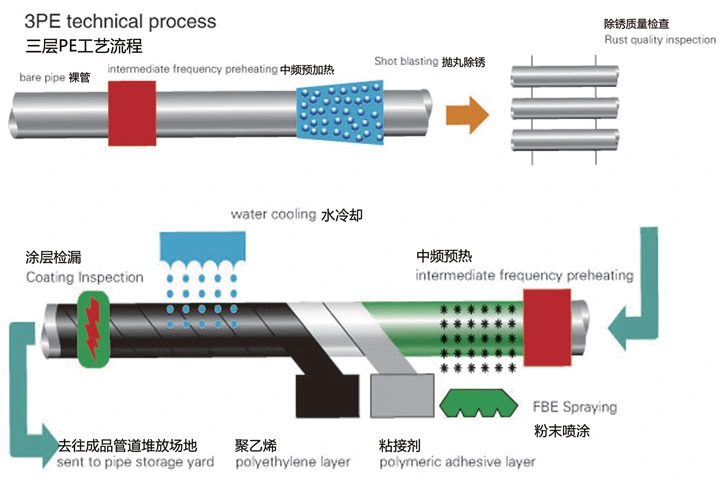

3pe- Steel Anticorrosion Pipe Coating Production description

Model:159-1400mm

Diameter range:159mm-1400mm

Extrusion Capability:≤350kg/h

Technological processes:

Upload pipes→pipes screw conveyor→rust removal of intermediate frequency heating→Epoxy powder coating→outer layer soli quid & polyethylene coating→cooling spray→pipes screw conveyor→grinding pipes, send→unload pipes

Our Services

3LPE coating processing line Quality guarantee period:12 months or 14 months from date of Bill of Lading.

During this period, the seller will provide free service for all problems caused by quality of equipments, however except the problems caused by the buyer .because of wrong operation.

Service:The seller would send technician to the buyer's factory to test the new machine and train people of the buyer. The buyer should pay for round-trip transportation expense, food, accommodation, insurance locally and related salary.

The traditional 3pe anti-corrosion production line generally has three forms, whether it is the double-layer epoxy powder Ownchart operation method, or the manual heating installation method of polyethylene heat shrink sleeve, there are obvious defects to a certain extent. How to avoid all the above defects has become the direction of technological development, and it is the purpose of achieving high-quality anticorrosion in the real sense.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!