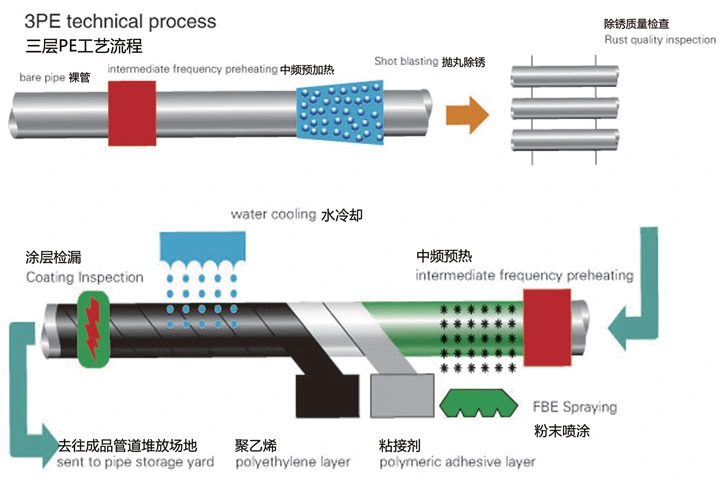

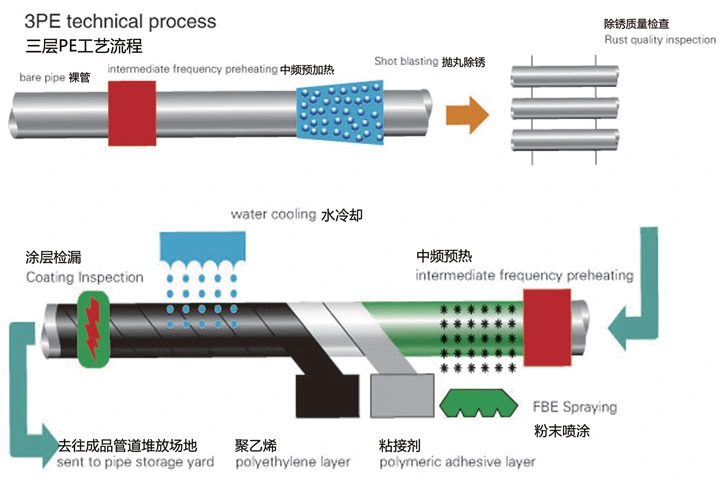

3PE anti-corrosion coating production line, diameter range Φ159 ~ Φ1220, the pipeline with three PE anti-corrosion structure: the first layer of epoxy powder (FBE> 100µm), the second layer of adhesive (AD) 170 ~ 250µm, the third layer of polyethylene PE 2.5 ~ 3.7mm. That is, by the bottom of the epoxy powder, the middle layer of adhesive, the outer layer of polyethylene composition of a corrosion structure, the three materials into one, and firmly combined with the formation of a good anti-corrosion coating. 3PE steel pipe outer coating is a high mechanical strength, excellent electrical insulation performance, high degree of mechanization of production lines, process parameters are relatively stable, does not pollute the environment, etc. In recent years, the pipeline corrosion engineering has been widely used.

| Steel pipe outside shot blasting derusting operation line |

| No. |

Description |

Qty. |

Remark |

| 1 |

Transmission line |

1set |

|

| 2 |

Shot blasting derusting line |

1set |

|

| 3 |

Cyclone dust collector |

1set |

|

| 4 |

Pulse filter cartridge dust collector |

1set |

|

| 5 |

Centrifugal wind blower |

1set |

|

| 6 |

Derusting equipment electrical control system |

1set

|

|

| Steel pipe outside spiral 3PE production line |

| No. |

Description |

Qty. |

|

| 1 |

Coating transmit system |

1set |

|

| 2 |

Intermediate frequency heating system |

1set |

|

| 3 |

Epoxy spraying system |

1set |

|

| 4 |

Automatic feeding dryer |

2sets |

|

| 5 |

single screw high efficiency extruder SJ-65/30 |

1set

|

|

| 6 |

SJ-120/30 extruder |

1set |

|

| 7 |

Hot melt adhesive extrusion die head |

1set |

|

| 8 |

PE sheet extrusion die head |

1set |

|

| 9 |

Hot melt adhesive/PE sheet press device |

1set |

|

| 10 |

Stainless steel spray powder chamber |

1set |

|

| 11 |

Cooling water spray system |

1set |

|

| Platform system |

| No. |

Description |

Qty. |

|

| 1 |

Steel pipe up load platform |

1set |

|

| 2 |

Derusting transition platform |

1set |

|

| 3 |

Finished pipe storage system |

1set |

|

| 4 |

Hydraulic system |

3sets |

|

| Grooving system |

| No. |

Description |

Qty. |

|

| 1 |

PE grooving device |

2sets |

|

| 2 |

Hydraulic elevating pipe turner |

2sets |

|

| 3 |

Operating cabinet |

1set |

|

Qingdao Huashi Da Machinery Co., Ltd. has advanced technology, mature professional and technical strength, for the vast number of old and new customers to provide the best quality service. Qingdao Huashida Machinery Co., Ltd. is a professional manufacturer of all kinds of anti-corrosion insulation equipment, the company's extruder, PE pipe black and yellow jacket extubation machine, traction machine, sealing machine, mold, polyurethane high and low pressure foaming machine , 2PE, 3PE winding equipment, groove machine, and dozens of kinds of pipe anti-corrosion insulation equipment. 3PE anti-corrosion coating production line was sold at home and abroad! Welcome new and old customers come to negotiate!

Specializing in the production of 3PE anti-corrosion coating production line 15 years, Qingdao Huashida Co., Ltd. has been adhering to the "credibility first, quality first" corporate philosophy and "customer first, moral business" business purposes, and continuously improve the quality of production lines and technical level. The customer concerning about the problem of service life, we make great efforts to carry out research, to achieve technological breakthroughs. The company is committed to building a management-based, customer-centric, science and technology as a precursor, engage in various types of anti-corrosion steel pipe production line, having been manufactured and sold dozens of 3PE anti- corrosion production line, at the same time to undertake 3PE corrosion, 2PE anti-corrosion, epoxy coal asphalt anti-corrosion, epoxy anti-corrosion, IPN8710 anti-corrosion, and other types of pipeline production line and provide a complete set of solutions. Companies adhering to the "first-class service, excellent quality, perfect after-sales" for the new and old customers to solve worries. Welcome the new and old customers advice. Hope customers to establish long-term cooperation and become a win-win partnership, sincerely welcome to our factory!

3pe- Steel Anticorrosion Pipe Coating Production description

Model:159-1400mm

Diameter range:159mm-1400mm

Extrusion Capability:≤350kg/h

Technological processes:

Upload pipes→pipes screw conveyor→rust removal of intermediate frequency heating→Epoxy powder coating→outer layer soli quid & polyethylene coating→cooling spray→pipes screw conveyor→grinding pipes, send→unload pipes

Our Services

3LPE coating processing line Quality guarantee period:12 months or 14 months from date of Bill of Lading.

During this period, the seller will provide free service for all problems caused by quality of equipments, however except the problems caused by the buyer .because of wrong operation.

Service:The seller would send technician to the buyer's factory to test the new machine and train people of the buyer. The buyer should pay for round-trip transportation expense, food, accommodation, insurance locally and related salary.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!