| No. |

Name |

Unit |

Qty |

Remarks |

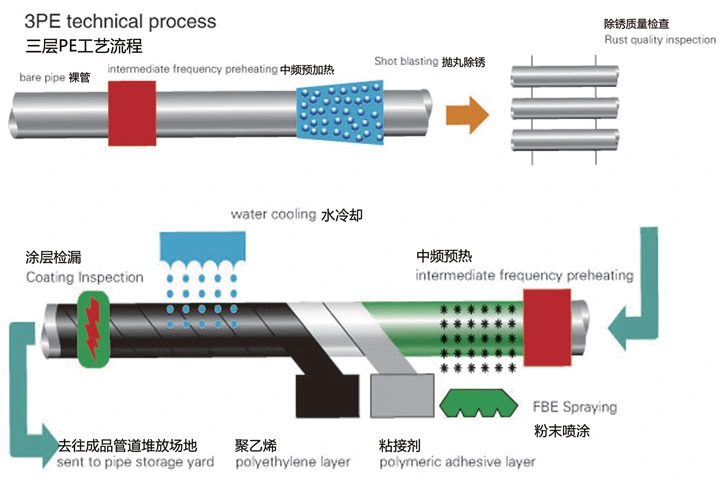

| External cleaning and 3PE system of the steel pipes |

| 1 |

Flatform of Upload pipes |

M |

15 |

Combination of dual structure |

| 2 |

Hydraulic tube pulling machine |

set |

8 |

Double lift,lifting force

more than 8T |

| 3 |

Air hydraulic station |

Set |

3 |

Air cooler, throttle valve |

| 4 |

Derusting spiral transmission line |

M |

27 |

Variable frequency speed regulation, solid tyre |

| 5 |

Synchronous dynamic spiral single-frame |

Set |

2 |

Variable frequency speed regulation, solid tyre |

| 6 |

The lower type shot blasting machine |

Set |

1 |

Max pipe diameter 1220mm |

| 7 |

Dedusting system |

Set |

1 |

first degree dust removal + pulse bag type dust collector |

| 8 |

transition platform line

|

M |

15 |

Combination of dual structure |

| 9 |

PE Spiral transmission line |

M |

54 |

Variable frequency speed

regulation,solid tyre |

| 10 |

Intermediate frequency heater |

Set |

1 |

800K

|

| 11 |

Dynamic high temperature roller |

Set |

1 |

Variable frequency speed

regulation |

| 12 |

Epoxy powder coating system |

Set |

1 |

Max pipe diameter 1220mm

|

| 13 |

The powder room, vulcanization barrel |

Set |

1 |

Non inductive heating

material |

| 14 |

two stage powder recovery device |

Set |

1 |

cyclones dust collector+

pulsed dust collector |

| 15 |

Automatic vacuum feeding machine |

Set |

2 |

800kg/h+300kg/h

|

| 16 |

SJ-180/30Extruder

SJ-180/30Extruder |

Set |

1 |

Q≈650kg/h

250KW DC,Q≈650kg/h

|

| 17 |

SJ-65/30 Extruder

SJ-65/30 Extruder |

Set |

1 |

45KW Q≈150kg/h

45KW AC,Q≈150kg/h |

| 18 |

Extruder moving mechanism |

Set |

1 |

Electric control |

| 19 |

Hot melt extrusion die head |

Set |

1 |

T die head |

| 20 |

PE sheet extrusion die mould |

Set |

1 |

T die head |

| 21 |

Hot melt adhesive

PE coating device |

Set |

1 |

Silicon rubber roller,

double cylinder, internal

water cooling |

| 22 |

Environmental protection ventilation system |

Set |

1 |

4KW

|

| 23 |

cooling spray system |

Set |

1 |

Water pump, water spray, pipelines, reflux tank |

| 24 |

The cooling splash-prevented plastic curtain-wall |

Set |

1 |

Approx 110m2 |

| 25 |

External anti-corrosion pipe unload platform |

M |

15 |

Combination of dual structure |

| 26 |

Pipe beveling grinding machine |

Set |

2 |

4KW motor electrical control system of walking |

| 27 |

Dedusting system |

Set |

2 |

Pulse dust collect |

| 28 |

Hydraulic lifting rotary pipe device |

Set |

1 |

Hydraulic lift,the four round of the WPA direct drive |

| 29 |

The electrical control system of 3PE steel pipes production line |

Set |

1 |

main line of centralized

control/individual/control

PLC Control

|

| compressed air system |

| 30 |

Screw type air compressor |

Set |

1 |

6m³/min,0.7MPa

|

| 31 |

freeze drying machine |

Set |

1 |

6m³/min,Enter temperature≤80ºC |

| 32 |

Precision filter |

Set |

3 |

0.1PPM

|

| 33 |

Gas tank |

PC |

1 |

1m³ |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!