China Three Calender Plastic PE PP Sheet Film Extrusion Machine Line Extruder,Low use cost

It consists of SBJZ-series plate &sheet special-purpose single screw extruder SJZ-series conical twin screw extruder Or SJ-series parallel twin screw extruder; Equipped with auxiliary downstream accessories and moulds, it can produce: PE, and other board & sheet.

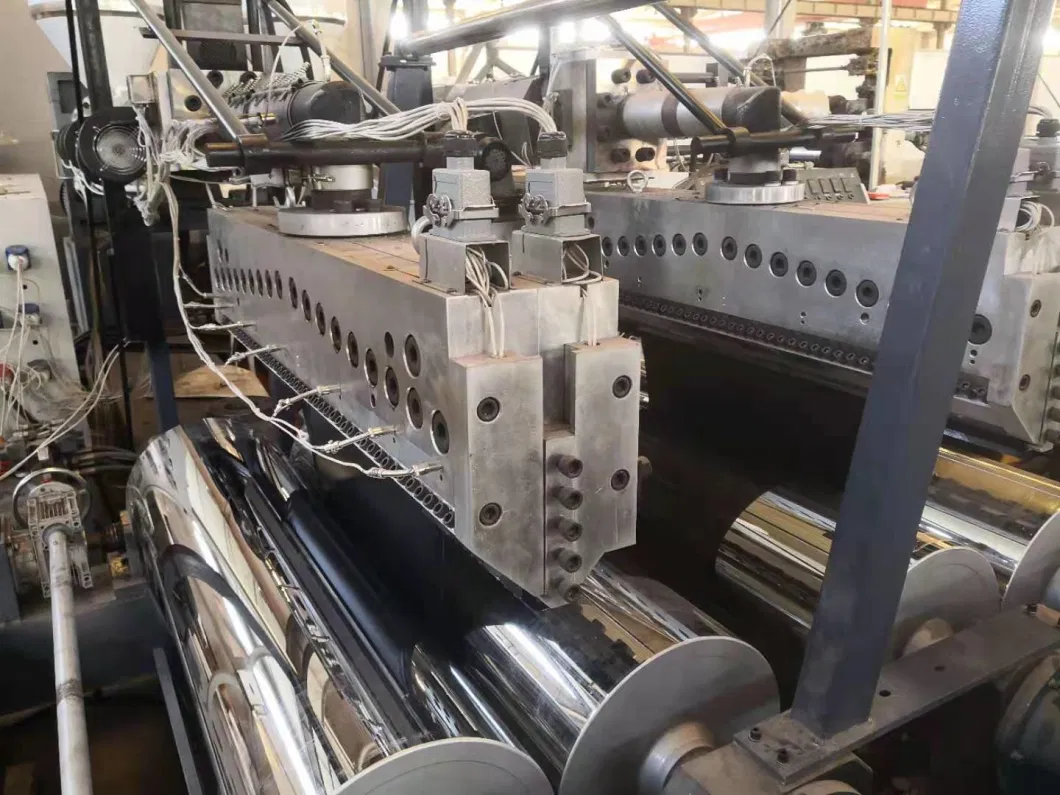

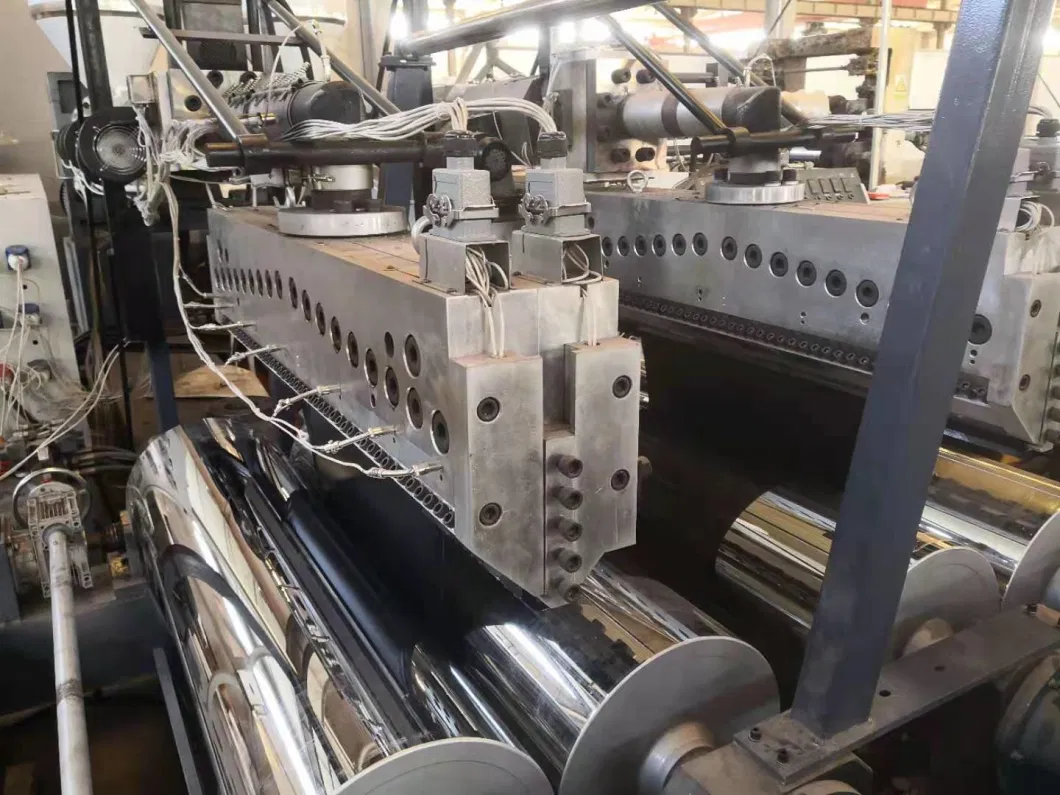

The machinery unit consists of extruder, Screen changing device, melt pump, T-die, 3-rollr or multiple-roller calender, cooling device, edge cutter, Haul-off system, plate cutter winder, electrical control system.

Others, The working principle is the 3 states of the hot-plastics at different temperatures: The pushing force of the screw change the physical stat from glass state to high elastic state, then glutinous-and-fluid sate, it comes out from the slim gap of the die, the rest of the procedures are calendar, cooling-shaper, edge-cutter, Haul-off, cutter, winder.

|

(Modle)

|

(width)

|

Thickness(MM)

|

Seedtm/min)

|

Outputr(kg/h)

|

|

SBJZ-800

|

650

|

0.18-1.5

|

1-25

|

80-320

|

|

SBJZ -1000

|

800

|

0.2-2.0

|

1-20

|

150-430

|

|

SBJZ -1500

|

1350

|

1-10

|

0.5-10

|

150-450

|

|

SBJZ -2000

|

1850

|

2-15

|

0.5-8

|

300-550

|

|

SBJZ -2200

|

2000

|

1-10

|

0.4-3

|

420-820

|

|

SBJZ -3000

|

2850

|

2-8

|

0.2-3

|

500-1200

|

|

SBJZ -7000

|

6800

|

2-6

|

0.2-2

|

600-1560

|

At present, the prevailing heat shrink belt production line in the market is produced by Qingdao Huashida Machinery Co., LTD. Because Huashida has advanced technology, mature experience, reasonable formula, and a supporting industrial chain up and down - both to do thermal shrink belt production line, but also to produce thermal shrink belt, but also to sell raw materials, so that Huashida's thermal shrink belt production line is used by everyone is really not a false head.

Heat shrink belt production line advanced production technology, simple process, improve production efficiency, reduce costs, scientific and reasonable design, in line with the production of high-quality heat shrink belt market needs, has become a high market share of the equipment, but also the majority of customers preferred production line equipment. The process of producing heat shrink belts is to produce plastic sheets, which are stretched and coated with glue after radiation cross-linking.

PC/PP hollow cross-section plate. PVC transparent soft & hard plat & sheet. PVC foamed plate, PMMA/ABS co-extrusion bathing plate, inside chamber plate of the refrigerator and other multiple-layer composite co-extrusion plate & sheet size: Width: 300MM-700MM thickness0.2MM-45MM: Output rate: 80-1800KG. /H. The machinery unit is the best solution for plate & sheet production.

HDPE SHEET EXTRUDER

PLC CONTROL SYSTEM

HDPE sheet can

Qingdao Huashida specializes in the production of radiation crosslinked polyethylene heat shrinkable belt (sleeve), mainly composed of substrate and hot melt adhesive. The company adopts a unique hot melt adhesive formula to ensure the adhesion of the product in use to ensure the construction quality. The optimized design of the new heat shrink belt (sleeve) is easy to field construction, fast shrinkage, short operation time, low construction cost, with excellent water vapor permeability, chemical corrosion resistance, insulation and aging resistance and other properties, is the ideal material for pipeline anti-corrosion insulation system

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!