3LPE /FBE pipe blasting/ coating/ PE film extrusion assembly production line

| production range |

processing capacity |

Cleaning class |

used material

|

| 159mm-1600mm |

159mm-1600mm |

Sa2.5 |

FBE powder, binder, polyethylene |

Description:

Qingdao Huashida Machinery Co., LTD. Steel elbow 3PE anticorrosive production line, mainly used in the manufacture and processing of oil and gas transportation, water supply transportation, sewage transportation, chemical transportation for 3PE anticorrosive bend (arc pipeline).

At least 16 groups of bending pipe conveying structure are arranged, the bending pipe is placed on the bending pipe conveying structure, the rotating shaft of the driving mechanism is driven by the rotating motor, and the rotating power is driven by the driving mechanism as the center. The center height of different pipe diameters is unified by the lifting device of the bending pipe conveying structure to adjust the height of the hanging roller.

Steel pipe conveyor system

1. Huashida pipeline rust removal production line, the selection of advanced hydraulic motor and hydraulic control system, PLC, inverter control, reasonable production line configuration, advanced control, environmental protection and energy saving, high production efficiency, is an important production line equipment before anti-corrosion liquid or powder coating in the pipeline.

2. The inner wall shot blasting machine is designed for high-efficiency production, and is mostly used for the spraying of oil, water and gas pipe fittings. The cycle and dust removal system of the production line is designed for fully automatic operation. The inner wall of the steel pipe shot blasting machine, the steel pipe after shot blasting can remove the corrosion and oxidation of the inner wall metal surface, obtain a certain roughness of the bright surface, to meet the requirements of the inner wall of the steel pipe before anti-corrosion, so as to improve the adhesion of the primer.

Application:

3LPE /FBE pipe blasting/ coating/ PE film extrusion assembly production line. The three-layer PE process, with the epoxy powder coating as bottom layer, binding and bundling through polyethylene PE and adhesive, is widely used in anticorrosion of steel pipes at home and abroad, and applied to the oil pipeline and gas pipeline, as well as to the gas supply and water supply for civil use.

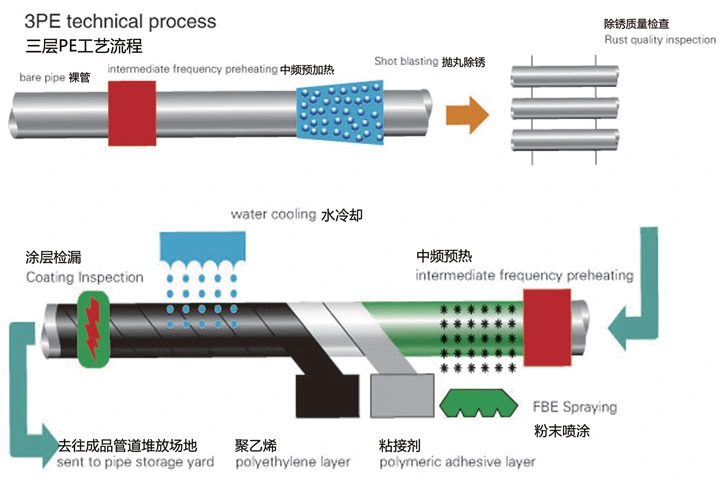

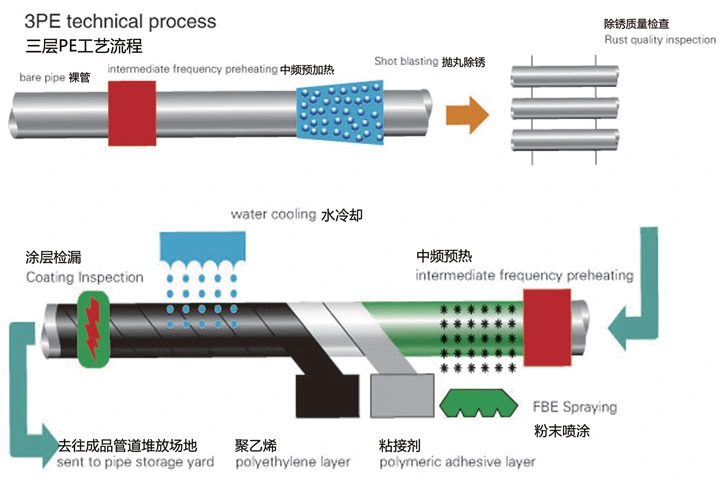

Technological processes:

Upload pipes→pipes screw conveyor→rust removal of intermediate frequency heating→Epoxy powder coating→outer layer soli quid & polyethylene coating→cooling spray→pipes screw conveyor→grinding pipes, send→unload pipes

Qingdao Huashida 3pe anti-corrosion equipment R & D team

Wu Daming, technical consultant of Huastar, is the deputy director of the College of Mechanical and Electrical Engineering of Beijing University of Chemical Technology, the deputy director of the Beijing Key Laboratory for the Preparation and Processing of New polymer Materials, and the expert committee of the China Plastics Processing Association. He has published 2 monographs, more than 150 scientific and technological papers, 16 patents, and more than 20 SCI and EI papers.

The technical consultant of Huashta is Wu Weiping, a bachelor of Chemical machinery from Beijing University of Chemical Technology, a master of engineering from the School of Mechanical Engineering of RWTH Aachen University in Germany, chairman of Shandong Alpur Energy Saving Equipment Co., LTD., a representative of the ninth National People's Congress, and currently a member of the Standing Committee of the Shandong CPPCC. The main research areas are plastic machinery, polymer materials, air source heat pump.

Zhou Kaitian, technical director of Huashida, graduated from Mudanjiang University majoring in mechatronic integration. He once worked in Hebei Zhongyuan Pipeline Group Co., LTD., Qingdao Okang Anticorrosion Co., LTD., responsible for the design of oversized pipe diameter anticorrosion production line and steel pipe inner and outer surface rust removal, surface spraying and 3PE anticorrosion non-standard equipment.

advantage

1, 3pe anticorrosive steel pipe has very high sealing, long-term operation can greatly save energy, reduce costs, protect the environment.

2, the construction is simple and fast, and the service life can reach 30-50 years.

3, also has good impact resistance under low temperature conditions, PE water absorption is low.

4, at the same time with high epoxy strength, PE low water absorption and hot melt adhesive softness, has a high anti-corrosion reliability, this anti-corrosion is characterized by simple production process, good anti-corrosion effect, low price, is the pipeline manufacturing industry generally recognized anti-corrosion method 2, oil and gas with three layers of polyethylene (3PE) steel pipe anti-corrosion, two layers of polyethylene (2PE) steel pipe anti-corrosion.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!