3LPE /FBE pipe blasting/ coating/ PE film extrusion assembly production line

| production range |

processing capacity |

Cleaning class |

used material

|

| 159mm-1600mm |

159mm-1600mm |

Sa2.5 |

FBE powder, binder, polyethylene |

Description:

Pipeline three-layer PE anti-corrosion structure: the first layer of epoxy powder (FBE > 100um), the second layer of adhesive (AD)170 ~ 250um, the third layer of polyethylene (PE)2.5 ~ 3.7mm. The three materials are integrated and firmly combined with the steel pipe to form an excellent anti-corrosion layer.

Pipe diameter range Φ159 ~ Φ1220 2PE anticorrosion: Pipe two-layer PE anticorrosion structure, the first layer of adhesive (AD), the second layer of polyethylene (PE), the two materials are integrated, the thickness of each layer is the same as that of three-layer PE.

Steel pipe conveyor system

1. Automatic conveyor adjustment as per pipe size controlled

2. Siemens PLC central control computer

3. Interactive human-computer interface screen

4. Customization according to user special require

5. Unified adjustment of opening and closing, unified adjustment of angle.

6. Each set of wheels is driven by independent power to expand the spiral angle of the conveyor, and the transmission angle can reach 30degrees.The transmission speed is adjustable from 0-6 meters.Adopt solid wide-surface tires, a single wheel with a load capacity of 2.5 tons,press-fit tires,no degumming, no cracking. The thickness of the glue layer is greater than 85 mm, the transmission is stable and reliable,and the safety guarantee for the long-term operation of the equipment.

Application:

3LPE /FBE pipe blasting/ coating/ PE film extrusion assembly production line. The three-layer PE process, with the epoxy powder coating as bottom layer, binding and bundling through polyethylene PE and adhesive, is widely used in anticorrosion of steel pipes at home and abroad, and applied to the oil pipeline and gas pipeline, as well as to the gas supply and water supply for civil use.

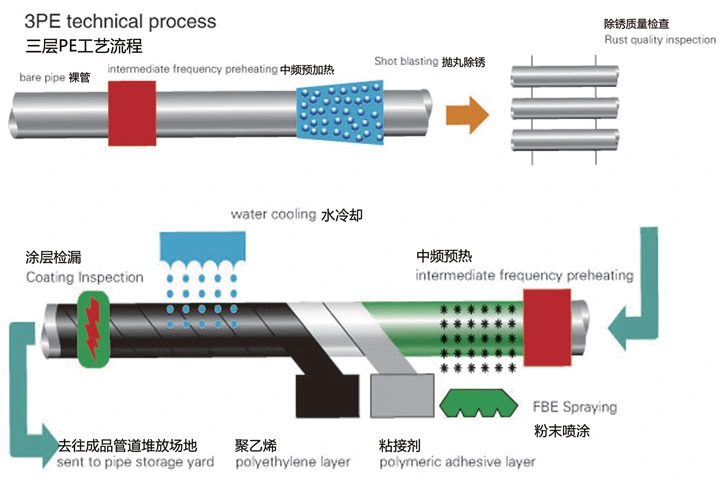

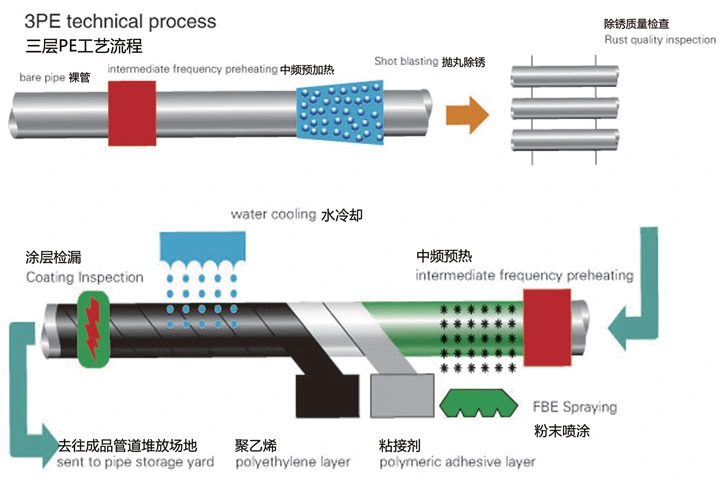

Technological processes:

Upload pipes→pipes screw conveyor→rust removal of intermediate frequency heating→Epoxy powder coating→outer layer soli quid & polyethylene coating→cooling spray→pipes screw conveyor→grinding pipes, send→unload pipes

Question & Answer:

Q1. What is Size of Pipe Dia. your equipment can produce ?

A: We can produce four main Model:

Diameter of steel Pipe:

48-219mm.

219-1220 - mm

800-1600 - mm

1000-2400 - mm

Q2. What is Descaling grade?

A:SA2.5?

Q3. What is your anticorrosion coating standard?

A: It can meet SY/T0413-2002 ,GB/T23257-2009, German DIN 30670 , DIN 30678 and coating specification requirements from American Corrosion Association, and DNV . The product pipe fully complies with SY/T0315-2005 ,CNPC38-2002 "Technical specifications for double-layer fusion-bonded epoxy powder coating on buried steel pipe and Canada, American Corrosion Association standards.

Q4. What is Delivery Time

A: 2-3monthes after deposit.

Q5. Production output:

A: It is different output capability as different pipe diameter, the Max. is 3 to 8 km/day, and annual processing capacity is 2 million square meters (Φ508 mm).

Q6. Coating thickness:

A: 80~800um

Q7. Which country did you sell your 3PE equipment?

A. We have produced nearly 50sets 3PE processing line at home and abroad. Such as Russia, Iran, UAE, Iran, India, Belarus, Kazakhstan and so on.

Q8. After-sales service:

A: Warranty period:

Before delivery all the equipment must be trial operated to confirm the quantity perfectly.

The warranty period is 12 months from the date of pick-up for mechanical part , and 6 months for the electrical part.

Service:

The seller provides free technical services and provides training and guidance to buyer operators.

advantage

1, 3pe anticorrosive steel pipe has very high sealing, long-term operation can greatly save energy, reduce costs, protect the environment.

2, the construction is simple and fast, and the service life can reach 30-50 years.

3, also has good impact resistance under low temperature conditions, PE water absorption is low.

4, at the same time with high epoxy strength, PE low water absorption and hot melt adhesive softness, has a high anti-corrosion reliability, this anti-corrosion is characterized by simple production process, good anti-corrosion effect, low price, is the pipeline manufacturing industry generally recognized anti-corrosion method 2, oil and gas with three layers of polyethylene (3PE) steel pipe anti-corrosion, two layers of polyethylene (2PE) steel pipe anti-corrosion.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!