Product Description

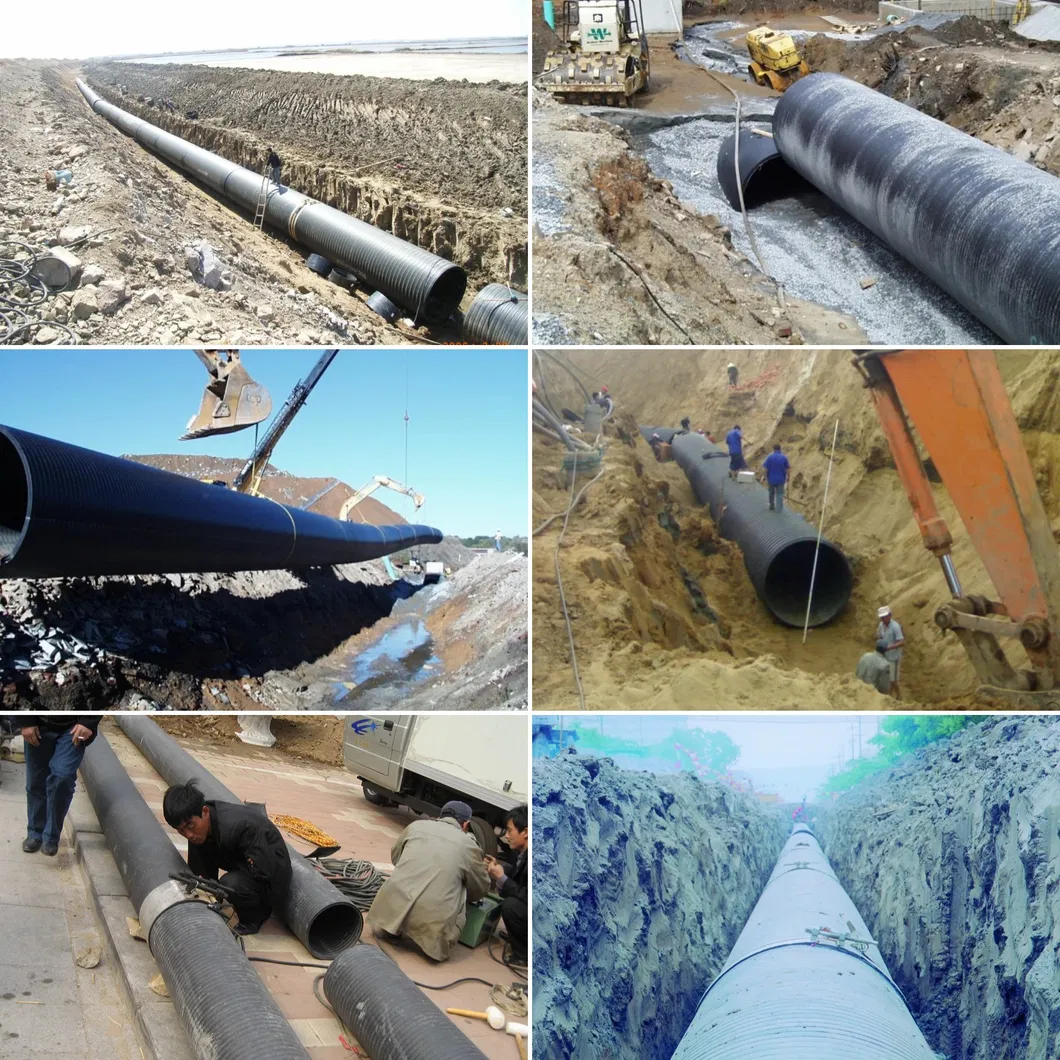

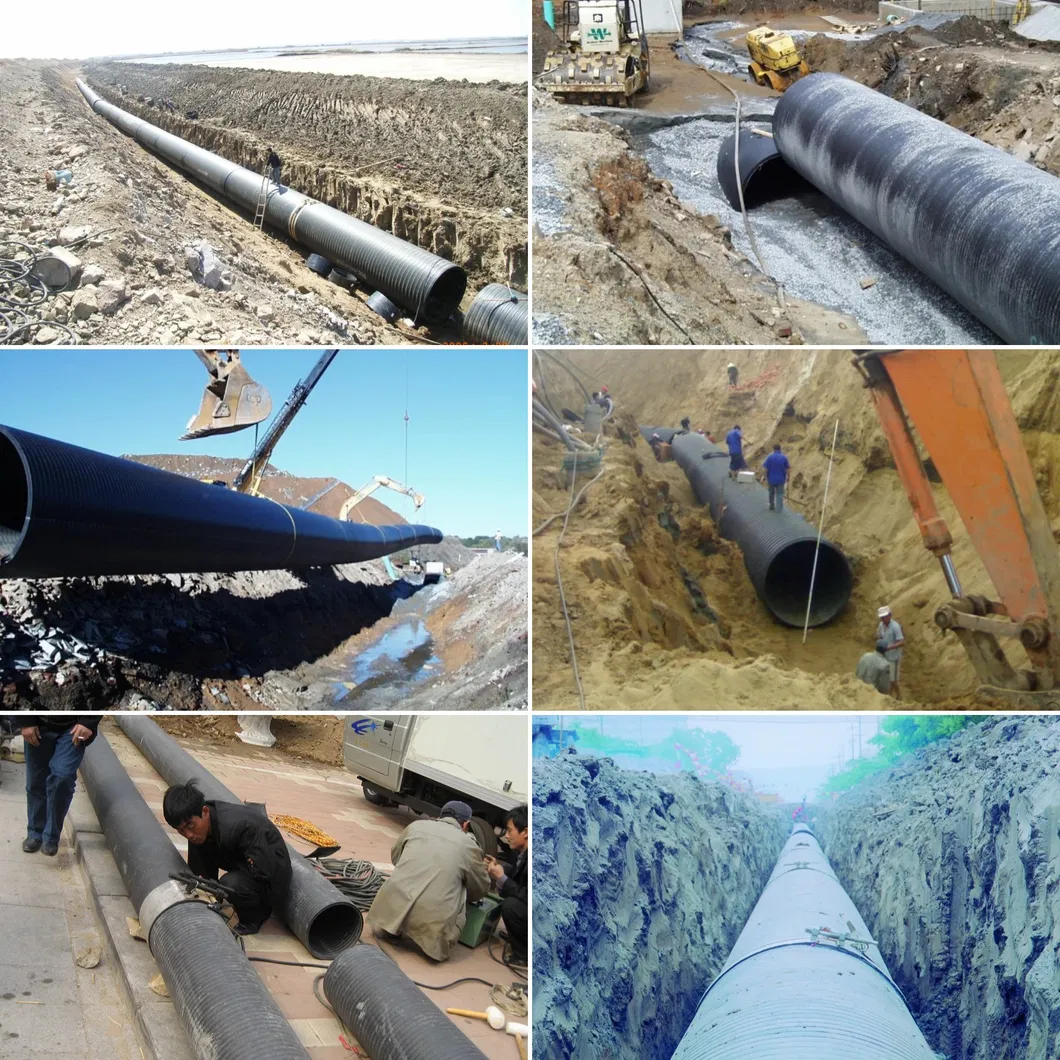

The HDPE Large Diameter Spiral Corrugated Pipe Making Machine, also known as the Krah Pipe or HDPE Spiral Wound Pipe production line, is designed to manufacture large-caliber spiral drainage pipes with a diameter range of 300-1200mm. These pipes are widely used in municipal sewerage and drainage systems, serving as a modern alternative to traditional cement and cast iron pipes due to their low assembly cost, ease of operation, reliable connections, and economical construction. The pipes offer high ring stiffness, high impact strength, low weight, excellent creep deformation resistance, outer pressure resistance, erosion resistance (against acids, alkalis, salts, etc.), and a long service life of approximately 50 years with no pollution.

The production line consists of two main parts: the PE Pipe Extrusion Line and the Spiral Forming Line.

PE Pipe Extrusion Line Components:

Vacuum Loader: Automatically feeds raw materials into the system.

Hopper Dryer: Dries HDPE material to ensure quality extrusion.

High-Efficiency Single Screw Extruder and Diehead Mould: Extrudes square-shaped HDPE pipes with low energy consumption and low-temperature plastication, suitable for high molecular weight materials. Features a unique screw design with solid-liquid separation and high mix-melting.

Vacuum Calibration Table: Ensures precise pipe dimensions during cooling.

Water Spraying Tank: Further cools the pipe to maintain shape and quality.

Hauling Machine: Pulls the pipe through the production line at a consistent speed.

Spiral Forming Line Components:

High-Efficiency Single Screw Extruder and Diehead: Extrudes melting glue material for bonding.

Spiral Forming Unit: Equipped with an advanced multi-axes transmission box for high transmission force and stable operation. Uses a composite die-head and rotational molding for spiral pipe formation.

Cutting Machine: Cuts pipes to desired lengths using a saw, controlled by an OMRON or MITSUBISHI PLC system with a touch screen interface.

Stacker: Collects and organizes finished pipes.

PLC Controlling System: Features a touch screen interface for automatic, reliable operation, synchronously controlling pipe extrusion, adhesive extrusion, winding, and cutting. Offers high-speed processing, large storage capacity, and dual touch screens for independent control of extruders and the winding unit.

Features

√ Advanced Extrusion Technology

√ Spiral Forming Unit

√ PLC Control System

√ Cutting Precision

√ High-Quality Output

Applications

Municipal sewerage and drainage systems

Replacement for traditional cement, cast iron, and other pipes

Applications requiring high durability, corrosion resistance, and cost-effective installation

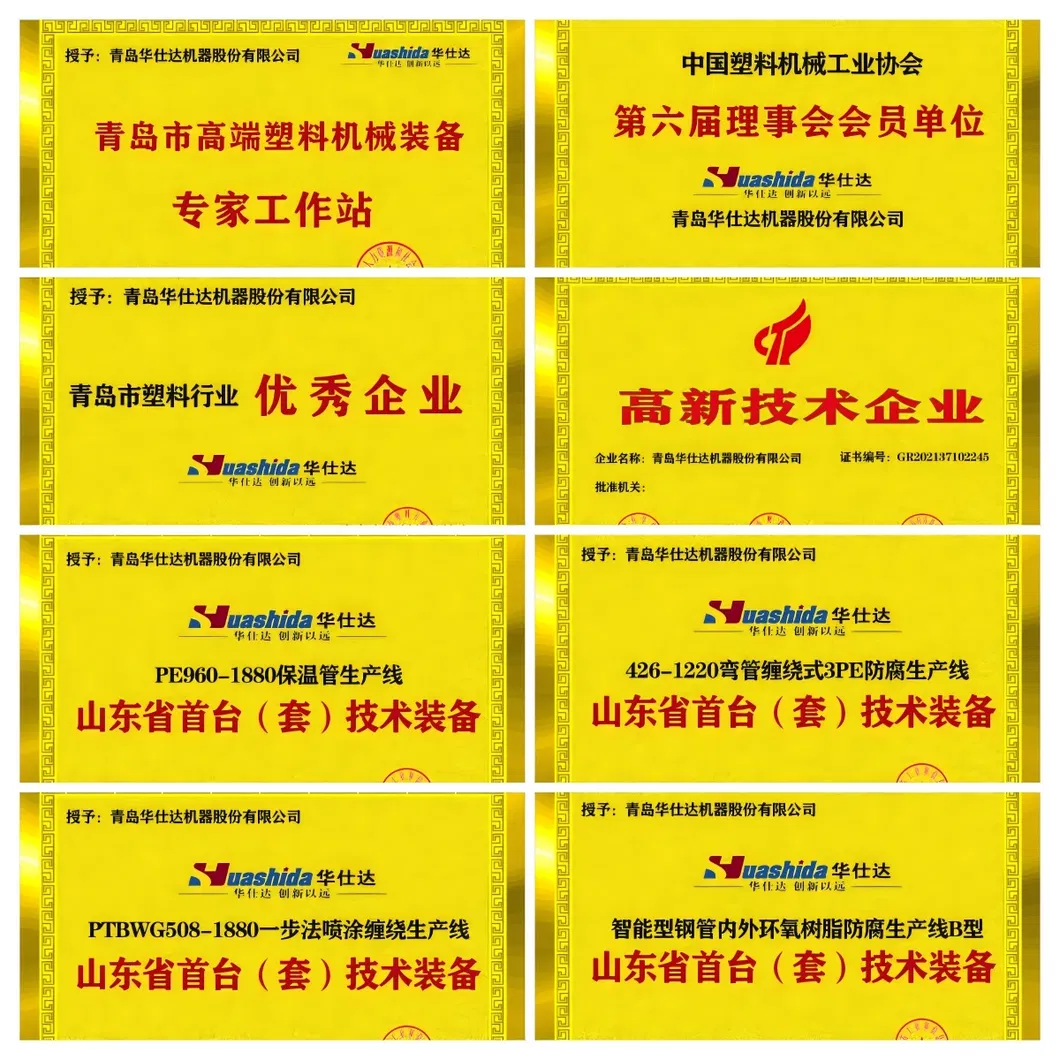

Company Profile

Qingdao Huashida Machinery Co., Ltd. is a specialized manufacturer engaged in the development and production of plastic pipe machinery, municipal pipe equipment, pipe insulation and anti-corrosion systems, as well as pipe jointing and anti-corrosion materials.

Our main product lines include:

HDPE Jacket Pipe Production Line for Pre-insulated Pipes (Diameter: 110-2000mm)

Rigid Pre-insulated Pipe Production Line

Flexible PERT Pre-insulated Pipe Production Line

Steel Pipe Anti-corrosion Coating Line for FBE, 2LPE, and 3LPE coatings

Steel Pipe Surface Derusting (Shot Blasting) Line

PE Pressure Pipe / Water and Gas Supply Pipe Extrusion Line

PP/PE Plastic Sheet, Board, and Geomembrane Production Line

NBR/PVC Thermal Insulation Tube and Sheet Production Line

Pipeline Anti-corrosion Materials & Tools, including:

○Heat Shrink Joint Coating Sleeves

○Electrofusion Weldable Joint Sleeves

○Portable Plastic Welding Guns (Extruders)

○ PE/PP Welding Rods

Certifications

Detailed Photos

- client -

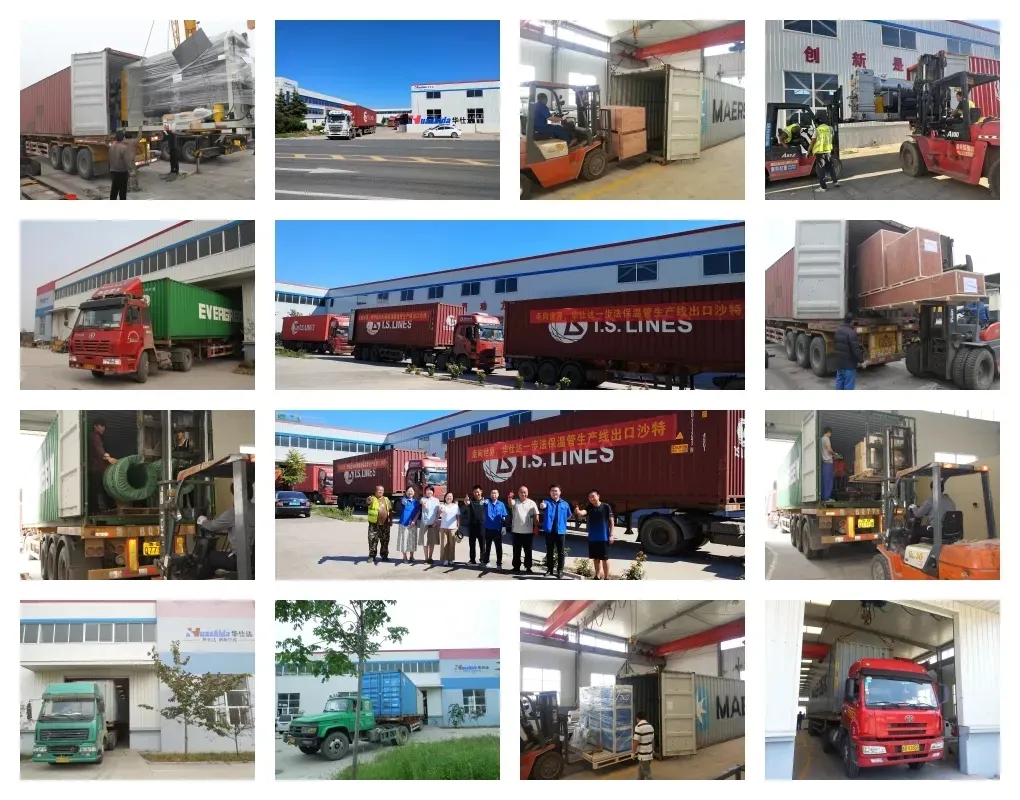

- packaging -

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!